No More Moiré: Remove Image Interference Without Sacrificing Resolution

You’ve probably seen a moiré pattern before, even if you didn’t know the name for it. Moiré (pronounced “mwah-rey”) is the French word for a type of rippled textile effect. In photography, it describes an interference pattern—a form of aliasing—that can appear on images. For example, moiré can be seen on standard photographic or video images that contain a pattern or repetitive detail that exceeds the resolution of the imaging device.

The namesake moiré patterning on silk (left), and an example of moiré pattern in a photograph (right).

Moiré is especially common when capturing an image of a television, computer, or other screen, where the frequency of the pixelated pattern on the screen is different from the frequency of the pixels on the image sensor array of the imaging device. The effect can pose a challenge for display test and measurement, when the image of a display device screen is captured by a digital photometer or colorimeter. Moiré occurs because there are tiny gaps between the pixels of both the display screen and the imaging sensor. When viewed close up or at high resolution, those gaps can be visible on the pixels of the sensors and appear as lines of various frequencies in the image, causing a moiré pattern when the pixels of the camera sensor array and the pixels of a display being imaged are not aligned.

A photograph of a television green screen exhibiting moiré effect.

Moiré Removal in Display Test Measurement

To test display devices for quality in the production process, we need to eliminate the moiré effect to obtain precise measurements and detect defects on the screen. Fine-grain defects such as lines and spots can be obscured by the moiré pattern in a test image, but will be visible to end consumers using the device.

Display test and measurement systems typically work by capturing an image of a DUT (device under test) and then analyzing that image to find any defects or quality issues. In high-performance display measurement solutions (such as Radiant’s scientific-grade ProMetric® Imaging Photometers and Colorimeters), images are captured by a high-resolution digital camera that receives electromagnetic radiation (light) from the DUT in the form of photons. The photons are absorbed by the detector array of an image sensor, and stored as electrons in the sensor pixels The charge accumulated in each pixel is linearly proportional to the amount of light received from the DUT, to create an image.

The image captured on the sensor is then read and processed by analysis software to detect any defects on the display. But first, other pre-processing steps may be required to clean up image noise and ensure accurate measurements can be made. Moiré removal is a critical pre-processing step to improve image quality prior to analysis that allows accurate assessment of the display.

Mura Detection

Another important “M” word is mura, from Japanese meaning blemish, unevenness, or irregularity. In the display industry, mura is the name for various common defects such as the lines, spots and non-uniformity. Manufacturers need to detect and measure mura so they can determine whether a display screen passes quality standards, fails but can be repaired or corrected, or if it must be scrapped.

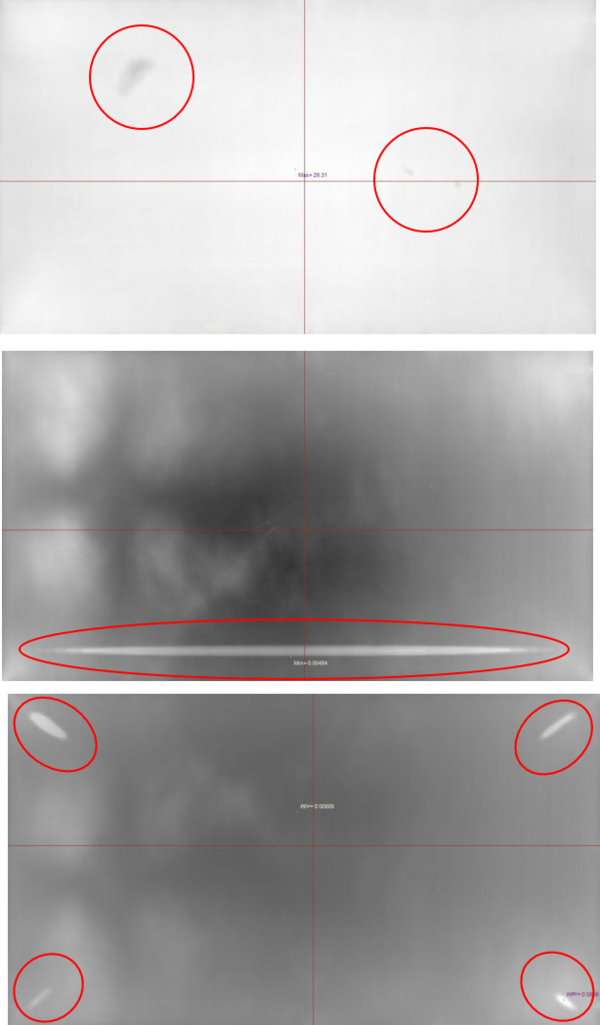

Examples of spot mura (top), line mura (center) and butterfly mura (bottom).

Moiré Removal

Display test and measurement system algorithms generally must perform a series of steps to accurately and repeatability find defects. There are different methods of removing moiré; a traditional approach suggests defocusing the camera to take the image.

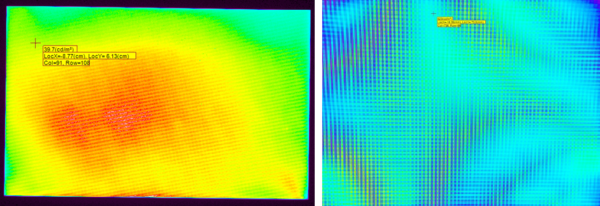

Example of a high-resolution image with moiré (left) and a defocused image (right). The moiré has been removed in the right-hand image, but the resolution has been sacrificed and the image appears fuzzy and out of focus.

While the defocusing method does eliminate any visible moiré, it also reduces the sharpness of the image and can compromise analysis precision. This approach can be sufficient for display analysis that doesn’t require high resolution, such as non-uniformity. Removing moiré by de-focusing an image can be effective, but only if high-resolution measurement and defect detection is not needed. For pixel-level defects and other small defects, only a software-based moiré removal approach will retain the resolution clarity needed for precision display measurement.

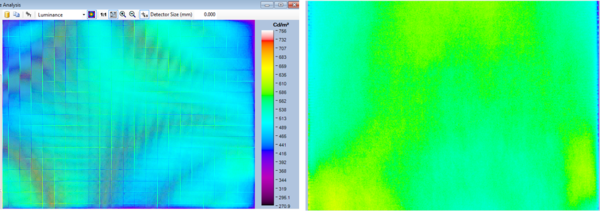

Moiré effects visible on images (using heat map coloration for demonstration purposes).

Where high-resolution defect detection and analysis is needed—for example, when inspecting pixel-dense and emissive displays such as LCD, OLED and microLED—sacrificing image resolution by defocusing the image is not an acceptable solution. Pixel-level defects will be missed unless you can retain the focus of the original high-resolution image. Radiant has developed a software-based moiré-filtering filtering approach that provides superior accuracy and high-resolution analysis. This solution provides the pixel-level precision needed to inspect today’s emissive displays.

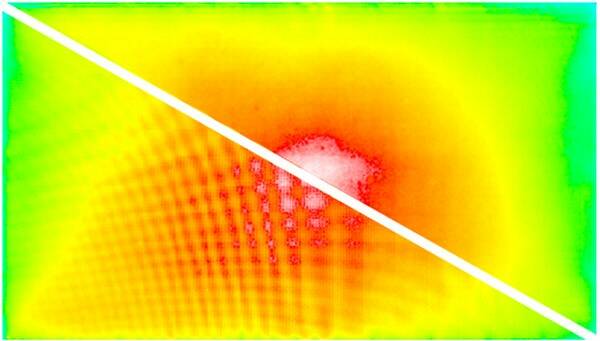

Moiré effect on a display image before removal (left) and the same image after moiré removal (right) with no loss of resolution (shown in false color).

Because moiré appears at regular frequencies, it can be isolated and removed in the frequency domain. Radiant’s TrueTest™ imaging processing software uses a frequency-based algorithm to automatically remove moiré artifacts. Moiré removal is not smoothing—a smoothing process actually destroys information that is needed for display quality inspection such as pixel defects.

Before moiré removal (left) and after Radiant’s moire removal has been applied (right) to eliminate the image aliasing.

Once an image has been filtered and moiré has been removed, then the system can appropriately detect and quantify mura and other defects on the display, down to the pixel and sub-pixel level.

Together, Radiant’s moiré filtering and mura correction approach provide a highly accurate display test and measurement solution for ensuring the quality of today’s high-resolution displays. To learn more about using high resolution images to detect pixel-level defects, moiré removal, and demura methods to measure and correct emissive displays, read the Tech Note: "Automated Visual Inspection and Correction (Demura) of OLED Displays."

Jessy Hosken is a Product Engineer at Radiant Vision Systems.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List