From high-speed, automated inspection systems for quality control on the production line, to high-precision solutions for R&D, Radiant‘s expertise in display test is unmatched. World leaders in consumer electronics and manufacturing rely on Radiant display test and measurement solutions to improve supply chain performance, reduce production costs, and ensure a high-quality end product. Our automated visual inspection systems accommodate multiple screen sizes and technologies, including LCD, OLED, microLED, projection, and more. Systems can be implemented throughout the display manufacture process to test display quality every step of the way for fully-automated quality control.

Backlight Units (BLU)

Uniformity Testing for BLUs

Light leakage and non-uniformity in LCD and LED backlight units (BLUs) can render the performance of a display unit unacceptable. The human eye can't test for these conditions with accurate and repeatable results. Using spot measurement devices provides insufficient information with unacceptably long cycle times. Radiant’s TrueTest™ Software comes with a library of predefined tests, including brightness and color uniformity, chromaticity, and contrast in panel display inspection—ensuring that every BLU meets performance standards.

Related Links:

Display Panel Modules

Detection of Foreign Material

For suppliers of glass, film, and other sub-assemblies, imaging colorimeters provide early identification of defects, reducing overall production costs by preventing additional investments from being made into flawed assemblies. Detection of foreign material, including dirt or fibers, can be performed at key points in the manufacturing process to avoid locking in these defects under film or glass. Unlike human inspection, a Radiant automated visual inspection system can find and size significant small defects, instantaneously and repeatably, regardless of their location.

Light Leakage

Light leakage is a common problem in LCD modules. It can be caused by physical damage during the manufacturing process or from faulty sub-components. Radiant’s TrueTest systems detect and classify light leakage problems before products leave the factory. Our proven technology provides repeatable and accurate results across multiple production lines and at different manufacturing locations.

Related Links:

Final Assembly

Quality Inspection of Consumer Electronics

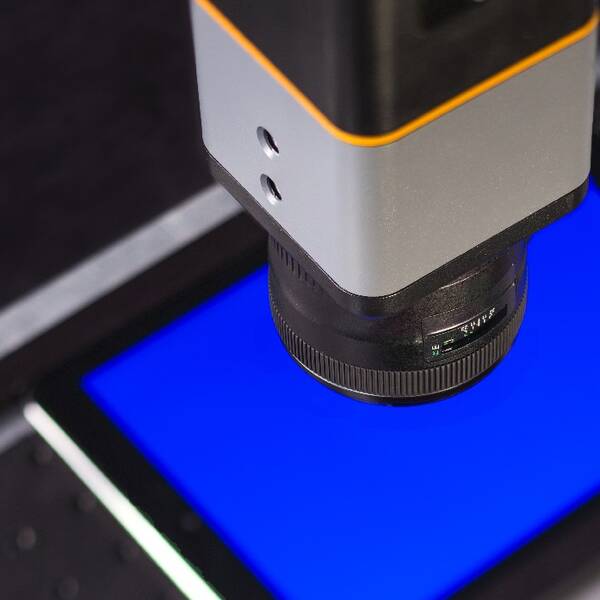

Makers of smartphones, tablets, and other display devices rely on Radiant to ensure a perfect end-user experience. An automated visual inspection system—comprised of TrueTest Software and a ProMetric® Imaging Colorimeter or Photometer—enables manufacturers to test display quality and identify defects with greater accuracy, efficiency, and completeness than manual inspection methods. You can tailor pass/fail criteria to address your unique quality concerns, including line and pixel defects, light leakage, non-uniformity, and mura detection. Radiant's systems also excel at assembly verification and surface inspection of non-illuminated components and assemblies.

Related Links:

Real-Time Calibration

From the Lab to the Line

Radiant solutions are adaptable to meet a variety of needs from R&D labs to quality control on the production line. With an end-to-end system, you have a common hardware/software environment for capturing seamless display measurement data throughout the device manufacture process. ProMetric I Imaging Colorimeters have NIST-traceable four-color factory calibration. This unique feature yields the highest color measurement accuracy when used in production environments.

Paired with a spectrometer, the ProMetric I camera can continue to perform four-color calibration on the fly so that device monitoring accuracy remains consistent with your display quality specifications on the line. If you have several line changes, the ProMetric I can auto-calibrate to new color thresholds for each new line of displays without removing the camera system from the line for re-calibration. For display manufacturers, this means that you can rely on the ProMetric measurement system to provide consistent, accurate, and repeatable data to support the high degree of precision needed for quality, for all types of display technologies, production lines, or manufacturing locations.

Related Links:

Embedded Displays

Quality Inspection and Defect Detection in Specialized Displays

Integrators of specialized displays for the automotive, aerospace, medical, and other industries need accurate quality inspection solutions to ensure consistent display performance in any environment. Radiant’s integrated inspection solutions allow you to focus on your total product, rather than the display alone. Leading manufacturers rely on Radiant to apply our expertise in display test for easy measurement and control of light, color, contrast, and viewing angle under changing lighting conditions.