Case Study: Inspecting EV Fuel Cell Layers

The market for electric vehicles (EVs) has been growing exponentially in recent years. In 2022, EVs accounted for 14%1 of all cars sold globally with China leading the way—more than half of cars on the road there are already electric.2 Demand for EVs is booming, expected to increase by 35% in 2023,3 as consumers respond to the fuel efficient and climate-friendly characteristics of these vehicles. Government policies are helping to encourage this seisemic shift in the transportation industry, after more than a century of dominance by the internal combustion engine.

Battery EVs and Fuel Cell EVs

There are two main types of EV engines currently in use, both providing the benefits of carbon-emission-free operation. Battery Electric Vehicles (BEVs) have "a battery pack that’s used to provide an electric current that powers your electric motor and thus propels the vehicle forward. The electric battery systems vary, but all of them have a basic anode, cathode and electrolyte system that converts chemical energy (stored) into electrical energy."4

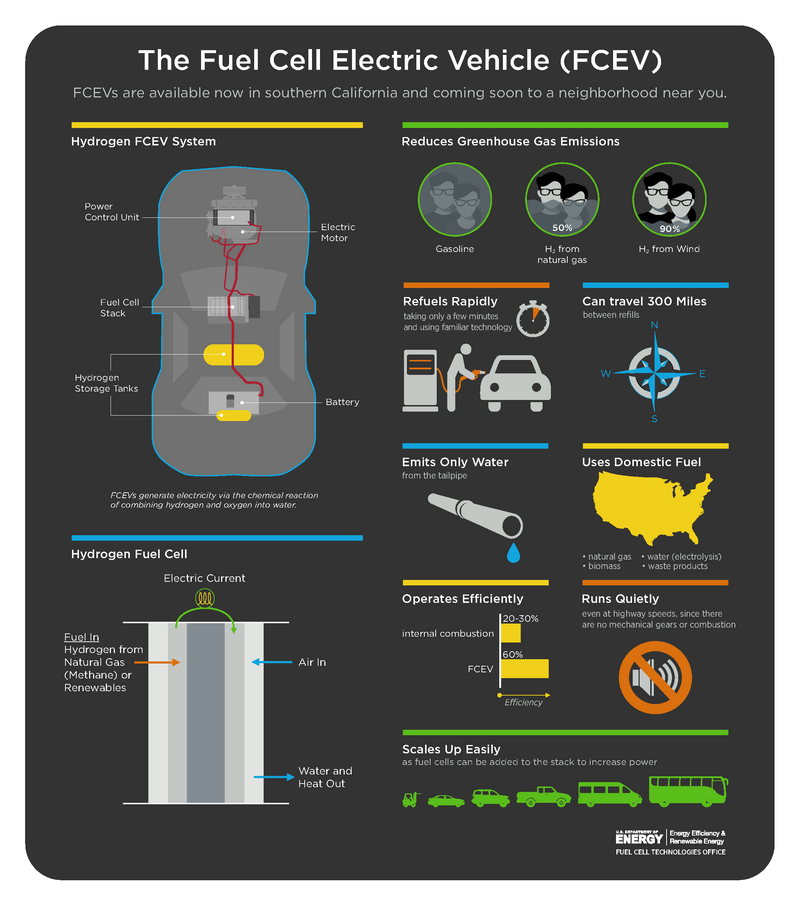

Fuel Cell Electric Vehicles (FCEVs or FCVs) use fuel cells to convert hydrogen to electricity to power the vehicle. "The chemical process that takes place involves an anode, cathode and electrolyte membrane system, similar to battery powered EVs, but with a few additional steps in converting the energy from hydrogen into electrical energy" to power the vehicle."5

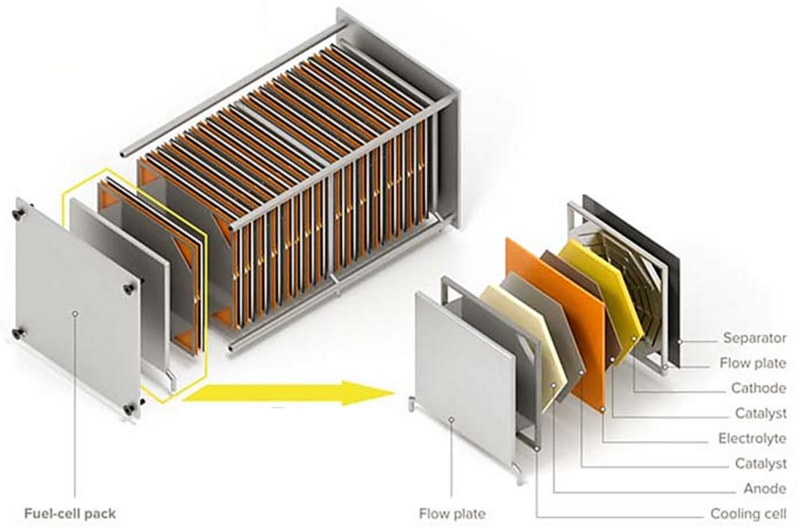

A single fuel cell designed for vehicle use produces "less than 1.16 volts of electricity—far from enough to power a vehicle. Therefore, multiple cells must be assembled into a fuel cell stack. The potential power generated by a fuel cell stack depends on the number and size of the individual fuel cells that comprise the stack and the surface area of the PEM [polymer electrolyte membrane]."6

Diagram of a fuel cell stack and individual layers.

Fuel Cell Inspection Case Study

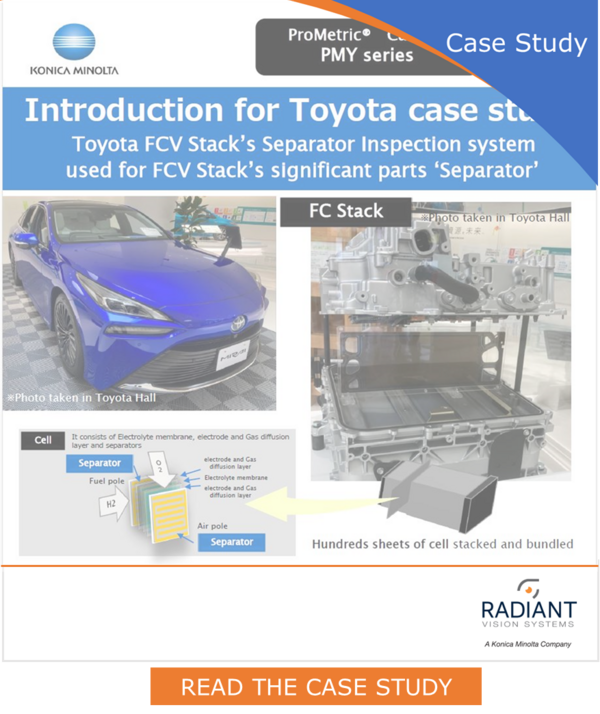

One company producing FCVs is Toyota. As the core component powering each vehicle, the fuel cells need to function flawlessly. This means the fuel cells must be free of any flaws or defects. Toyota needed a method to inspect both sides of the separator used in fuel cells for its FCVs. Traditional machine vision cameras did not produce clear images to detect small scratches and fine dirt.

The fuel cells use PEMs. Multiple PEMs are layered together sandwiched between positive (cathode) and negative (anode) electrode layers. Separators (also called biopolar plates) are used to assemble these layers into stack and provide channels for the gaseous fuel and air. Scratches and particles on the separators can interfere with the performance of the fuel cell.

In this case study, learn how Toyota worked with Konica Minolta to implement a solution using Radiant's ProMetric® Imaging Photometer, TrueTest™ Software, and a custom lighting configuration to perform visual surface inspection of the fuel cell separators.

CITATIONS

- Global EV Outlook 2023, International Energy Agency (IEA), Paris , License: CC BY 4.0

- Ibid.

- "Demand for electric cars is booming, with sales expected to leap 35% this year after a record-breaking 2022", International Energy Agency (IEA), April 26, 2023.

- "Battery Electric Vehicles vs. Fuel Cell Electric Vehicles," Toyota of Downtown LA website,(Accessed August 15, 2023)

- Ibid.

- "How Fuel Cells Work," US Department of Energy (Retrieved August 15, 2023).

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List