Light sources have a significant impact on device design and operation in all industries. From backlit avionics in an aircraft to illuminated components in medical equipment, the brightness, color, temperature, and uniformity of lighting are essential for conveying visual information or helping users accomplish critical tasks. For instance, lighting in an airplane cockpit must be sufficiently bright and correctly distributed to allow a pilot to see important instruments as he flies. Color also plays an unsung but critical role.

The color rendering of organs and tissues under various lighting colors and temperatures can affect a surgeon’s ability to visually distinguish color differences that indicate tissue types and health. Lighting for medical devices and other equipment used for healthcare must fall within specific color and temperature ranges to ensure visual information is not misinterpreted. Achieving the intended performance of each light source requires measurement of the photometric characteristics of each light, which differ for LEDs to halogen and incandescent lamps. Measurement solutions help designers meet desired light output across emission angles, colors, reflections, contrast, and patterns for a given application.

Radiant’s measurement solutions for light source design and production capture complete and precise three-dimensional spatial measurements of a source’s output (creating standard IES, EULUMDAT (LDT), and Radiant Source Model™ (RSM) files), which can be exported for use within optical design software. Radiant light measurement systems measure luminance, illuminance, luminous intensity, chromaticity, Correlated Color Temperature (CCT), and more, to determine that a source is designed to spec, manufactured without flaws, and binned appropriately.

Radiant’s solutions for light source measurement employ ProMetric® Imaging Colorimeters and Photometers for the quickest and most comprehensive evaluation of millions of data points, which ensure all light sources meet your specifications and the expectations of your customers.

Solutions for Light Source Characterization

Radiant solutions for light source measurement include photometric light and color measurement technology—from goniometric systems, which measure light as a factor of angle, to non-goniometric systems, which measure luminance or overall illumination patterns. These systems can be applied in design and quality control to accomplish all phases of light source manufacturing, from source modeling and characterization to in-line production. The choice to perform light measurement using either a goniometric or non-goniometric system comes down to restrictions on measurement space, and the scope or type of measurement data that must be acquired. Radiant’s goniometric and non-goniometric solutions are outlined below.

Goniometric: Near-Field Measurement

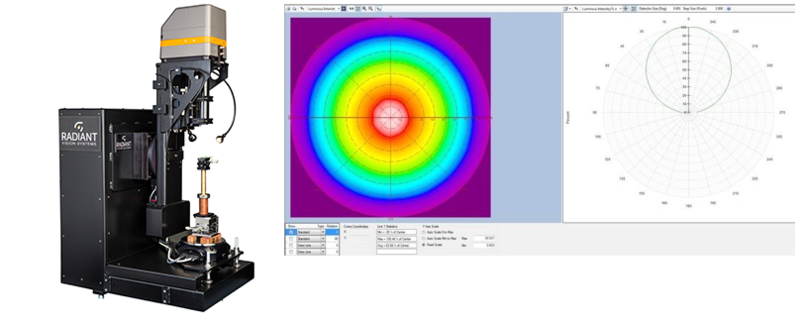

Radiant goniometric solutions employ a goniometer (SIG-400 for LEDs and small luminaires) to model a light source using near-field measurement methods. A goniometer measures the luminance (Lv) and luminous intensity distribution (candela) of the source, accounting for the spatial origin and angle at which the light is emitted—providing a complete understanding of the light source’s output as seen at any distance. Because imaging systems measure the precise spatial position and angle of the light source, the dimensions of the light source (for instance, an LED) influence the illumination pattern and therefore affect the measurement data.

Goniometric systems generate ray set data to quickly output IES, EULUMDAT (LDT), and Radiant Source Model™ (RSM) files (or, luminance data for measuring Unified Glare Rating (UGR)). Beneficial for lighting design, IES, LDT, and RSM files can be exported into common optical design ray-tracing software (such as ASAP®, FRED®, LightTools®, LucidShape®, Opticad®, OSLO®, OpticStudio™ (ZEMAX), SimuLux®, SPEOS®, TracePro®, Photopia™, and IES TM-25).

Features of a near-field measurement system:

- Combines a goniometric system (such as a Radiant goniometer) with an imaging colorimeter or photometer (such as a Radiant ProMetric imaging system)

- SIG-400 — goniometer engineered to measure small light sources (such as individual LEDs)

- Models the complete spatial and angular output of a light source

- Takes approximately 1,500 measurements to output a complete characterization

- Requires limited measurement space (<5m)

- Can be used to extrapolate far-field distribution (or ray-traced) data from Radiant Source Model (RSM) files

An example of a goniometer (left) employing an imaging system to measure the complete spatial output of a large light source at a given angle. A measurement image (right) shows the radar plot of a light source’s angular luminous intensity distribution (in false-color scale) and a polar diagram highlighting a cross section of that intensity plot.

Non-Goniometric: Far-Field Measurement

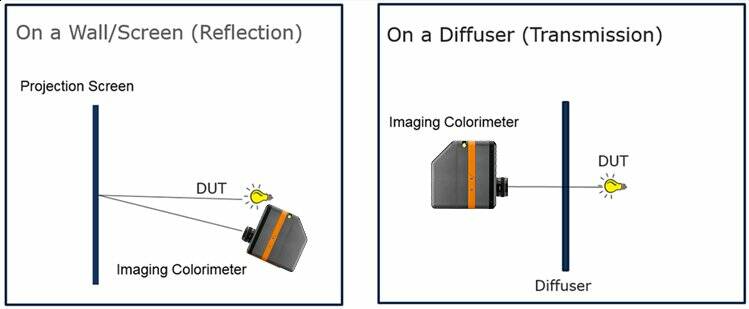

Radiant’s non-goniometric solutions employ an imaging colorimeter or photometer to measure a source using far-field measurement methods. In far-field distribution measurement, the ProMetric imaging system is mounted on a tripod and positioned facing a surface to measure light cast on a wall or through a diffuser. This allows the imaging system to capture both the illuminance distribution as well as calculate the luminous intensity of the light source from a single measurement. This measurement technique can be applied in the lab or during production within a designated measurement space on the line. Measured values include luminous intensity (cd), which is the luminous flux (lm) in a given direction. A far-field measurement system measures the beam pattern cast by a light source, so the dimensions of the luminaire itself (for instance, an LED strip) do not influence the measurement data the way they do in near-field measurement scenarios.

Non-goniometric systems generate IES files for lighting design and bitmap files (captured by imaging systems). Beneficial for lighting design, IES files can be exported into common optical design ray-tracing software (such as ASAP®, FRED ®, LightTools®, LucidShape®, Opticad®, OSLO®, OpticStudio™ (ZEMAX), SimuLux®, SPEOS®, TracePro®, Photopia™, and IES TM-25).

Features of a far-field measurement system:

- Uses only an imaging colorimeter or photometer

- Measures illumination distribution (beam pattern) of any light source (size of the source has no influence on the measurement of the light pattern)

- Takes a single measurement to output a complete characterization of the source

- Can be used for quality assurance in high-volume manufacturing operations

- Light can be cast against a wall or screen to measure light (reflection of the source)

- Measure light through a diffuser (transmission of the source)

Examples of non-goniometric measurement setups using an imaging colorimeter to measure the beam pattern of a light source reflected off a wall or screen (left), or through a diffuser (right).

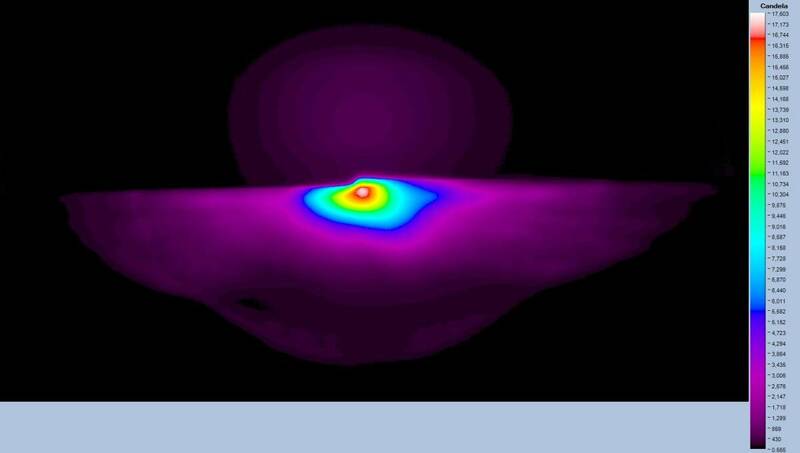

Measurment image showing the distribution pattern captured by an imaging system from light cast on a wall by a headlamp (shown in false-color scale in Radiant PM-HL™ Headlamp Evaluation Software).

Measuring LED Arrays

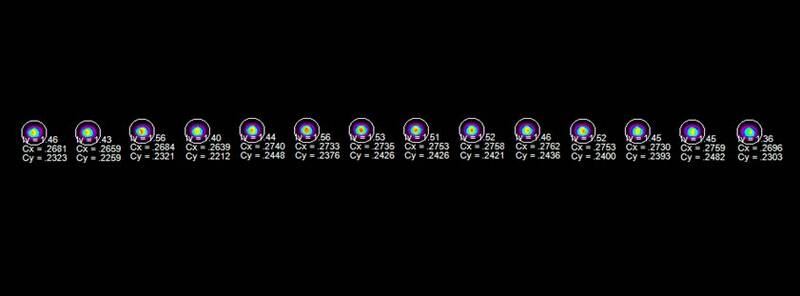

LEDs are manufactured to precisely match design specifications for color, luminance, and color temperature. Radiant ProMetric Imaging Colorimeters and Photometers combine sophisticated optical filters (providing unrivaled match to CIE color-matching functions) with patented ProMetric calibration technology to provide the most accurate, complete measurement data in a single image. These systems leverage the speed and space-efficiency of a compact image-based system—ideal for high-volume production lines—and are capable of measuring hundreds or thousands of small light sources simultaneously in arrays, on PCBs, or as installed in backlit components like backlight units (BLUs) and LED light strips.

Radiant TrueTest™ Software measures an LED array for intensity and color during in-line quality inspection.

Solution Comparison

Radiant Light Source Measurement Systems

| Near- or Far-Field | Solution | Measurement Method | Data Sets |

File Output |

Typical Space Required |

Typical Measure-ment Time |

Typical Applications | |

|---|---|---|---|---|---|---|---|---|

| Goniometric | Near-Field | SIG-400 (Source Imaging Goniometer™) | The imaging system is rotated relative to the light source, capturing measurements of the source at all angles. |

|

|

< 2 m | 1-4 hours | Light source modeling for lab and R&D applications. |

| Non-Goniometric | Far-Field | ProMetric® Imaging System |

Light from the source is cast on a wall or screen and measured by an imaging colorimeter or photometer

|

|

|

-10X size of the light source | 1-2 sec | Qualification of small to large light sources, either in the lab or in production settings |

| Direct Measurement | Single light sources or light source arrays are measured directly by an imaging colorimeter or photometer |

|

|

< 1 m | 1-2 sec | Production-level testing of LEDs, LED arrays, and backlit components like LED light strips |