Electronic devices use color and light to convey digital information to users via illuminated controls and high-resolution displays. The use of display-based technologies has extended beyond televisions, computers, and phones to appliances, toys, wearables, and other devices. The visual quality of these products not only enables functional operation but defines the customer experience and satisfaction. Device designers and manufacturers must meet ever-increasing consumer expectations for exquisite display quality.

Radiant Vision Systems applies decades of experience in automated visual inspection at all stages of the design and manufacturing process, leveraging our history in light and color measurement and our expertise in production-level display test solutions. We support major consumer electronics manufacturers worldwide, and understand that a flawless device is a prerequisite for market success. We work closely with you to provide comprehensive solutions that support your operating imperatives—increasing throughput, reducing rework, and achieving absolute quality.

Radiant’s TrueTest™ Software offers production-level quality control and an extensive library of tests. Our ProMetric® Imaging Colorimeters and Photometers feature advanced optical filters that simulate human visual perception of light and color, providing the truest evaluation of quality your customers will see. An integrated system from Radiant helps you to ensure that each device meets your standards at every stage of manufacture – and, meets your customer’s expectations in today’s competitive marketplace.

Display Testing

All Display Technologies from LCD to OLED

As the leading provider of display test solutions worldwide, Radiant has thousands of systems currently deployed testing millions of smart devices, touchscreens, infotainment panels, embedded displays, and other display devices. A broad range of tests can be performed on LCD, OLED, and other display types using a Radiant ProMetric Imaging Colorimeter or Photometer paired with TrueTest™ Software, including:

- ANSI brightness

- ANSI color uniformity (CIE x, y and CIE u’,v’ coordinates)

- light or color mura (blemish) detection

- light leakage

- pixel and line defect inspection

- image sticking

- view angle performance

Radiant’s automated visual inspection systems weigh and evaluate defects based on severity and scope, which correlate to either permissible or unacceptable imperfections as they would be perceived by a typical human observer. With scientific-grade, high-resolution, cooled image sensors, ProMetric cameras capture high-resolution images in a single measurement while minimizing visual noise. This ensures that you have the clearest images for fine-detail and pixel-level defect inspection.

Related Links:

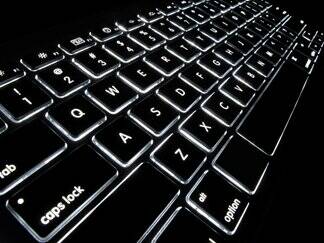

Keyboard Inspection

Radiant’s portfolio of inspection solutions includes software specially engineered for testing illuminated keyboards, keypads, and control panels in high-volume manufacturing environments. Using our automated visual inspection on the production line, you can ensure perfect final assembly of backlit keys and components, safeguarding device usability and ensuring long-term product quality.

ProMetric imaging solutions and the PM-KB™ Illuminated Keyboard Testing module for ProMetric Software let you apply unique tools for inter- and intra-character luminance and color uniformity and perform optical character recognition (OCR) to ensure keys are easily viewed and properly installed in their correct locations. OCR technology can also be applied to verify the accuracy of character print location or quality.

Related Links:

Cosmetic Surface & Glass Inspection

Scratched, dented, and otherwise imperfect products result in costly returns and may damage your brand’s reputation and future business. Quality control operations that are intended to prevent surface defects rely largely on human inspectors to ensure faulty products are not shipped to consumers. However, the faster the production rate, more complex the product, or more obscure the defect, the more difficult it is for humans to keep up with throughput demands while maintaining consistent quality.

Our industry-leading technology for light measurement can be combined with select machine vision tools to accomplish challenging inspection applications of non-illuminated surfaces and components, including device covers and electromechanical assemblies. Radiant systems capture high resolution images with low noise and high dynamic range to capture the greatest range of grayscale values. These capabilities yield images with the clarity and contrast to enable detection of fine details that typical machine vision systems miss (such as fine scratches on metal surfaces, or particles on or trapped between glass and transparent layers.

Related Links:

Assembly Verification

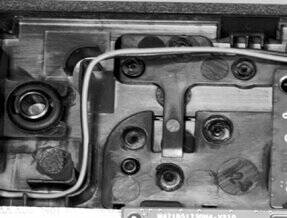

Inspecting Internal Assemblies, External Components, and Final Assembly

Smart devices, computers, and electronic assemblies require precise and complex configurations of components to ensure proper form and function. Inspection standards are high. Yet even if a product passes functional testing, the slightest error in cable routing, missing screws, or connector misalignment can drastically reduce a product’s lifecycle and result in latent errors that may lead to product failure as it is used by the consumer over time.

By combining a ProMetric® Imaging Photometer, external lighting, and a range of machine vision software tools, manufacturers are able to image and inspect complex assemblies in-line during production. Surpassing machine vision systems for visual acuity, Radiant’s photometry-based solutions identify feature location, perform presence/absence checks, measurement, and more, by leveraging the superior resolution and dynamic range of the ProMetric imaging hardware.

Our photometers can detect the greatest range of contrast variances within an image (such as a dark screw on a dark surface, or a white wire on a light surface) and evaluate anomalous contrast differences within a wide area that may indicate damaged or defective components. Using automated inspection to acquire quantifiable data on electronic assembly defects, Radiant systems allow manufacturers to analyze trends regarding where and when defects occur, which may indicate a problem at an earlier stage of production, and enable data-driven operational improvements that support lean production.

A Partner You Can Trust

Information Security, Confidentiality, and Supplier Integrity

Radiant Vision Systems partners with leading consumer electronics manufacturers to produce the world’s most competitive products. We understand the need for absolute confidentiality surrounding technology development, operational practices, and other proprietary information. Our code of conduct enforces strict protection of customer information, and has earned us the trust of leading brands worldwide.