Virtual reality (VR), augmented reality (AR), and mixed reality (MR) devices rely on the quality of near-eye displays (NEDs) to deliver a seamless immersive or integrated experience. AR/VR/MR displays project visual objects and information in close proximity to the human eye—encompassing the user’s entire angular field of view—so that visual details created by variations in the brightness and color of the display are magnified to create simulated and augmented worlds. However, this proximity also magnifies what would be unnoticeable display defects if seen at a distance.

Subtle defects and anomalies can include:

- Non-uniformities in brightness or color

- Contrast issues

- Mura (cloudiness)

- Line & pixel defects

- Focus uniformity issues

- Distortion or ghosting

- Image retention/sticking (or pixel switching response time)

Display defects have a critical impact on your users’ experience, potentially obstructing visualization and device operability. Additional considerations include image distortion and inconsistencies from eye to eye (color, angle, parallax), which can further impact user experience and result in eye strain or even motion sickness.

It requires sophisticated inspection capabilities to achieve the product quality customers demand. Radiant Vision Systems is a pioneer in display testing for AR/VR technology, offering the highest spatial resolution in light and color measurement for detecting, classifying, and preventing subtle light uniformity issues and pixel and sub-pixel defects. Radiant has developed inspection solutions that replicate the human eye’s visual response in a wide range of:

- Visual experiences (immersive or see-through)

- Display types (LCD, OLED, microLED, LCoS, or DLP)

- Viewing channels (monocular, binocular, or bi-ocular)

- Optical design (opaque display, free space, freeform, lightguide / waveguide, metasurface, holographic, curved mirror, birdbath, or custom optics)

Microdisplay Testing

High-Resolution, Pixel-Dense Displays

The highest-resolution LCD, OLED, microLED, projection, and other display technologies are integrated into today’s near-eye display devices, with more pixels per eye contributing to the realism of the user experience. Manufacturers are also reducing hardware size for wearables like head-mounted display (HMD) devices, employing the latest microdisplay technology to reduce weight and size. With such high pixel densities within the tiny area of these displays, you need high resolution imagers to evaluate device accuracy and projected image clarity.

Radiant’s ProMetric series of imaging colorimeters and photometers offer a range of high-resolution sensor options for capturing ultra-fine inner- and intra-pixel uniformity defects. These image sensors are optimized to reduce noise in image capture, increasing signal-to-noise ratio (SNR) for accuracy, and ensuring the highest-quality images for analysis.

ProMetric imagers can be paired easily with specialized optics to perform small-object and view angle analyses. Radiant’s AR/VR lens features an optical design that replicates the human pupil size (3.6 mm) and eye position within headsets (with an external aperture for positioning the imaging entrance pupil at the headset lens). This, combined with a horizontal field-of-view to 120 degrees, enables the system to measure the display from the vantage point of a human user.

The same ProMetric system can be used to measure microdisplays outside of a headset, with interchangeable lenses that accommodate measurement over a wide range of working distances and view angles. For view angle performance measurement, Radiant’s FPD conoscope lens evaluates displays to 0.06 degrees per sensor pixel at a single measurement point. The lens captures luminance, radiance, angular contrast, CIE chromaticity coordinates, and correlated color temperature (CCT) for consistency across all viewing angles simultaneously.

Related Links:

Measuring Augmented Projections

Projections of AR and MR displays are superimposed over a user’s visible surroundings to supplement the real world with digital information. As with head-up displays (HUDs) used in the latest automotive and aerospace technologies, these projections must seamlessly blend and interact with physical elements in view at a variety of locations and depths. To function correctly, AR and MR projections require precise control of position, light, and color for viewing on an infinite plane.

AR and MR displays are extremely susceptible to errors in visual depth when projections are not mapped correctly for parallax (accounting for the horizontal distance from eye to eye). Devices must be able to match the size, shape, and position of projected images as viewed in each lens—or in each display in the case of binocular devices. Object position, brightness, color, and contrast are critical benchmarks of depth and location relative to surroundings. As a designer or manufacturer, you must be able to control each factor to ensure that projected content is bright enough to be seen, but also does not obstruct the user’s view of the real world.

The Power of ProMetric for Precise AR Measurement

ProMetric imagers have helped to define the baseline SAE (Society of Automotive Engineers) testing parameters for HUDs in the automotive and aerospace industry, where the accuracy of projected data is a critical safety factor. Radiant’s expertise in precision visual display measurement is also applied to AR and MR displays. Our imagers can measure objects projected into infinity, using highly-sensitive scientific-grade image sensors to locate superimposed objects projected into an ambient environment. ProMetric cameras feature:

- Electronically controlled lenses that allow you to remotely adjust camera focus and aperture settings. These cameras are uniquely capable of locating augmented projections

- Advanced software algorithms that use focal settings to measure size and position to determine object “distance” in real-world measurements without the need for focal depth calculation

- Light and color accuracy measurements to determine accurate brightness (highlights or shadows) in respect to the environment, contributing to the projection’s visibility

- Evaluation against defined tolerances for luminance, color, and spatial offset. You can accurately determine an artificial object’s location, depth, and size

- Library of tests and patterns such as checkerboard patterns to measure slant edge contrast or modulation transfer function (MTF) to ensure object clarity

Related Links:

Software Tools for AR/VR Display Testing

Radiant’s TrueTest™ Software platform helps AR/VR designers and manufacturers to maintain quality for any illuminated display technology. TrueTest includes the leading display test algorithms for absolute luminance and chromaticity characterization and analysis. Standard tests include:

- Brightness

- Color

- Uniformity

- Line Defects

- Pixel Defects

- Contrast

- A range of mura (blemish) tests

Radiant also offers a specialized test suite for AR/VR display analysis that includes:

- Line Pair or Slant Edge Contrast (for MTF measurement based on ISO 12233)

- Image Distortion (for distortion characterization)

- Focus Uniformity

- Image Ghosting

- x,y positions given in degrees (°)

These tests have been developed to meet the unique requirements of AR/VR display testing, allowing you to achieve light and color quality and image accuracy for high-resolution displays viewed near-to-eye.

Radiant’s AR/VR lens replicates the human pupil position within headsets to capture the full visible field of view of integrated, high-resolution displays, as viewed by the user.

Related Links:

Factory Calibration

Every system Radiant provides is calibrated for a unique measurement application (utilizing customer-specified filters, optics, and other parameters) here at our factory to ensure that absolute data is reliably captured when the system is used for measurement at your facility. A common effect of optical solutions developed for AR/VR display measurement is inherent distortion in images captured by wide-field-of-view optics that are used for full display measurement. Radiant performs distortion calibration on each camera/lens solution to ensure that the system delivered to you for your measurement application will capture normalized images for testing.

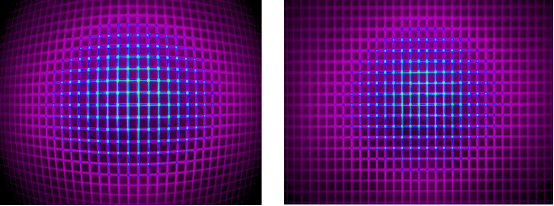

Wide-field-of-view images taken by a camera/lens solution before and after distortion calibration. Distortion calibration of each system eliminates lens effects in wide-field-of-view images to ensure accurate spatial data is acquired by the software before testing.

Complete Project Support Worldwide

With a global network of sales, technical support, and engineering resources located across the United States, Europe, China, Japan, and Korea, our local professionals are here to see your project through from start to finish. Radiant’s portfolio includes configurable software, modular imaging systems, and accessories, giving you a single solutions provider to address all aspects of your test and measurement application. Whether you need a system for R&D, quality control, or production – or systems throughout the complete device manufacturing cycle – our staff partners with you to specify and implement your unique solution, and offers technical support long after your system is deployed.