Simultaneous Production Inspection of Light, Color, and Defects in Backlit Symbols

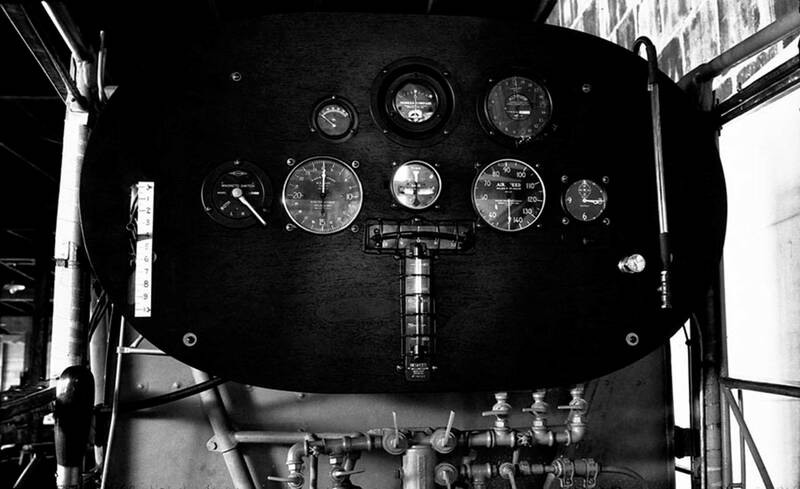

In May 1927, Charles Lindbergh made history completing the first transatlantic flight. He piloted his airplane the Spirit of St. Louis from Long Island, New York to Paris, France in 14 hours and 25 minutes. The aircraft had only a simple cockpit with a handful of gauges and controls, knobs to switch between fuel tanks—and no lighting. Airplane cockpit design and illumination has come a long way in the 95 years since then. A typical jet now incorporates multiple illuminated symbols and controls, display screens, and both interior and exterior lighting.

The instrument panel and fuel manifold of the Ryan NYP N-X-211 Spirit of St. Louis (Photo: © Donald A. Hall Photograph & Document Collection)

Backlit signs and symbols have become a key component of aviation safety. They have also become commonplace in automobiles, for signs in public spaces, on medical equipment, for industrial control panels, and on illuminated computer keyboards, among multiple applications.

Examples of backlit symbol applications, top row left to right: device controls and keypads, instrument panels and avionics, computer keyboards; middle row: automobile dashboards (left), controls (center), and LED-backlit light strips and shapes (right); bottom row left to right: vehicle mirror blind spot indicators, airplane safety symbols, illuminated signs.

In the aviation and automotive industries, backlighting is often used to spotlight key buttons and controls, and illuminated symbols provide critical information to the operator, such as warning lights. In these heavily regulated industries, specifications for the appearance of various backlit elements are precise. Illuminated elements must meet stringent standards for brightness (luminance), color (chromaticity), clarity, and shape to ensure they are visible and legible to the pilot or driver—in any ambient lighting condition, day or night.

Modern pilots rely on an array of backlit indicators and controls alongside various displays in the cockpit of a Boeing passenger jet.

Quality Issues with Backlit Symbols and Signs

Backlit symbols are typically made by placing a layer (such as an opaque film) in front of a light source (such as an LED array). The top layer is stenciled, for example with laser cutting, to form letters, icons, and shapes. Some defects in the resulting symbols can result from errors in the cut out—such as a missing element (exclusion), an extra element (inclusion), misshapen elements, or symbols in the wrong location or orientation (rotated). Manufacturers must inspect backlit panels to correct these types of errors.

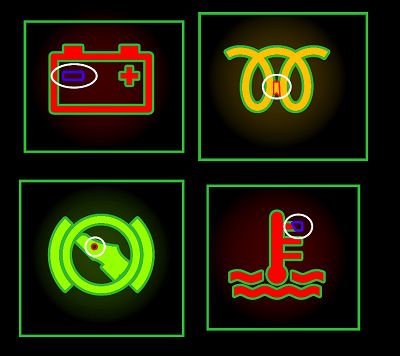

No driver looks forward to seeing these backlit symbols (low oil, check engine) while driving, but we can all be grateful for a clear early warning to prevent vehicle damage or breakdown.

To comply with safety requirements, manufacturers of backlit panels and films must also meet strict light and color tolerances across all regions of a panel or sign. In production, this means testing for any variability in the backlight as seen through the overlay. Quality issues may be caused by the lighting array—such as LED luminance values that don’t meet required brightness, or color that is inconsistent across a sign or from symbol to symbol.

Inspection to Meet Regulatory Standards

Radiant’s light and color measurement systems are used to ensure uniformity in backlit signs and films that are used for public signage, aerospace cabins, directional and information panels, and appliance controls. Radiant's VIP™ (Vision Inspection Pack) license with TrueTest™ software combines photometric measurement capabilities with defect detection to identify inclusions, exclusions, and other symbol integrity issues. Our imaging technology can test multiple areas simultaneously, capturing and processing data much faster and more consistently than a human inspector or a spot measurement device.

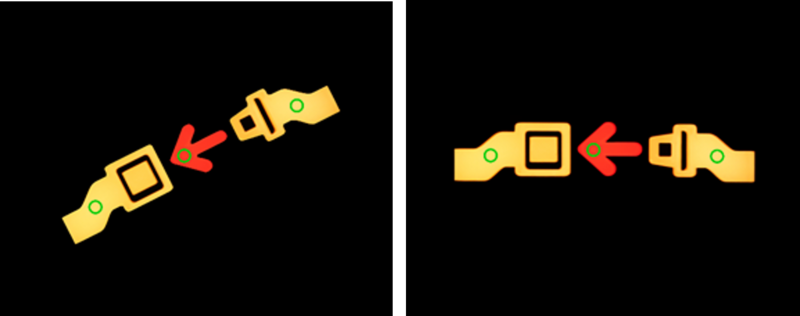

Examples of inclusion and exclusion defects, as detected by Radiant’s VIP™ (Vision Inspection Pack) software.

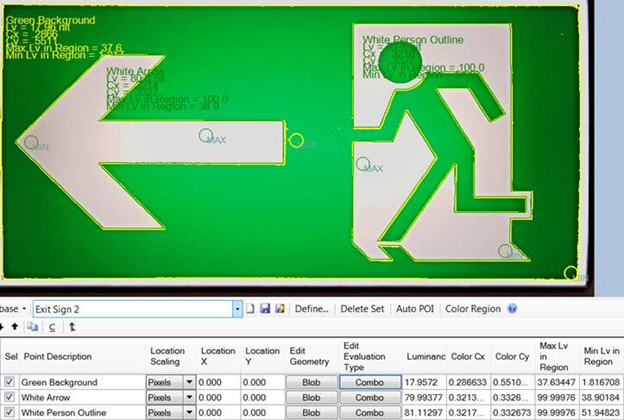

Used with a ProMetric® I Imaging Colorimeter, VIP lets users measure average luminance of each colored region, minimum and maximum luminance points, color uniformity in each region, and dominant wavelengths. Manufacturers can ensure the visibility and legibility of illuminated icons, text, and shapes, obtaining precise measurements of luminance and chromaticity and detecting nonuniformity in backlit symbols, buttons, switches, indicators, and light strips.

A single image capture in VIP software includes responsive symbol registration, unlimited user-defined POI (points of interest) for photometric measurement (luminance, chromaticity, and more), and automatic defect detection of inclusions, exclusions, and other shape deformations.

Machine Vision + Photometric Capabilities = A Complete Solution

With VIP, Radiant offers the first complete solution for backlit symbol inspection, which simultaneously performs photometric measurement of light and color along with machine vision-based registration and defect detection. With both capabilities in a single system, VIP greatly improves the efficiency of measurement for both product development labs and for production-line inspection. VIP helps manufacturers meet component quality and performance requirements outlined in standards for industries from automotive to aerospace.

Leveraging machine vision software functionality, the VIP solution applies Radiant’s TrueTest™ photometric analyses for luminance (cd/m2), chromaticity (CIE xy, u’v’), and other values within the precise registration areas of unique shapes such as icons, text, and other backlit components. VIP helps manufacturers ensure that trained measurement regions are free from inclusions or exclusions caused by inaccurate laser etch or errors in overlays, filters, or other substrate layers.

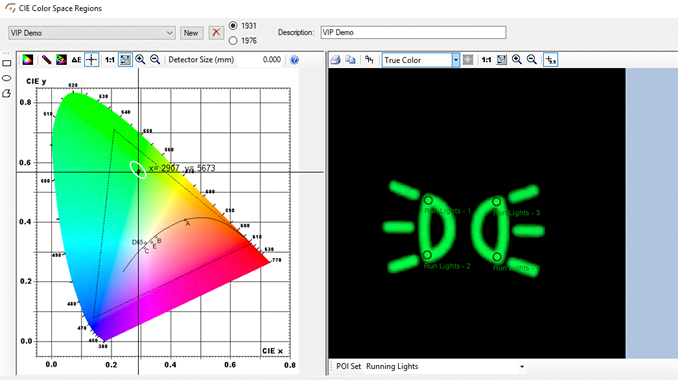

Users can set pass/fail tolerances for photometric and colorimetric values measured within VIP registrations regions, including specific POI. In this example, the four POI on the Side Lights indicator (right) are shown plotted on the CIE color space (left) based on their chromaticity (xy) coordinates. A user-defined ellipse on the CIE color space sets the chromaticity tolerances for pass/fail based on measured POI color coordinates.

Dynamic Registration

In high-throughput inspection applications, VIP provides an efficient solution for rapid registration of multiple symbols and shapes captured within a single measurement image, quickly applying trained registration regions to multiple components inspected in series. Registration regions can be applied globally (across multiple symbols) to ensure the accuracy of relative symbol locations, sizes, orientations, and aspect ratios; or locally (symbol by symbol) to dynamically register each symbol for measurement and defect detection.

VIP automatically locates and registers symbols in new orientations (as components move or rotate) while maintaining the same relative placement of custom POI within each registration region. This dynamic registration capability ensures all symbols in a series of components are consistently measured based on the same POI locations, without requiring users to maintain exact fixturing tolerances or reapply registration regions or POI for each component measured.

VIP saves POI locations for each registration region, ensuring consistent measurement of each icon or shape (such as this airline "fasten seatbelt" icon) even if components move or rotate.

To learn more about backlit symbol inspection considerations in the automotive industry, and how photometry and machine vision capabilities combine to solve previously complex visual inspection challenges, read the article “Machine Vision and Photometry Inspect Automotive Symbols,” published in Vision Spectra magazine.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List