Solving the Hard Inspection Problems: Beyond Machine Vision

“Hard” inspection problems are ones that push the limitations of any visual inspection method—human or machine. As electronic and mechanical devices become more complex, assembly verification requires inspection of multiple features simultaneously and at high speed. Complex assemblies can contain many small parts or low-contrast elements that are difficult to assess at production speeds.

If not caught, subtle defects—such as misrouted cables, missing screws, or misaligned connectors—can escape and end up in customer hands causing latent failures. The cost of these failures can be severe in terms of returns and warranty claims, customer dissatisfaction, and damage to brand reputation.

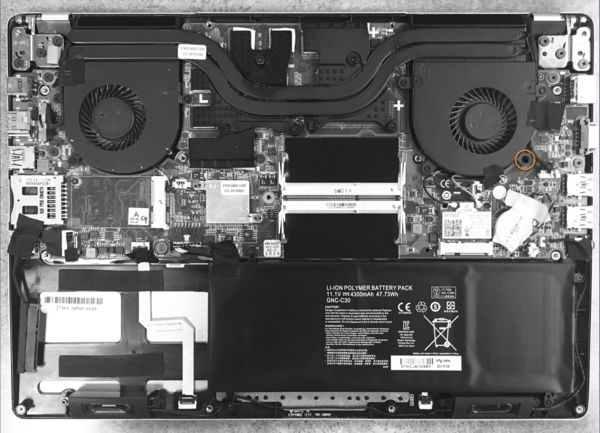

The internal assembled components of a complex electromechanical device…with one missing screw.

In an article published in Vision Systems Design Magazine, we examine the strengths of human and machine vision inspection methods as compared with the latest advances in photometric and machine learning technologies. How well does each inspection method—humans, machine vision and machine learning, and photometry-based Advanced Vision—perform at spotting and quantifying defects to prevent escapes and latent failures?

Human inspectors offer superior visual acuity, but their performance can be compromised by scene complexity, time limitations, and fatigue. Traditional machine vision systems offer speed and repeatability, but are challenged by high dynamic range, low contrast scenes and by subtle variations. They have difficulty discerning up to 20% of defects, such as those that are random or unexpected.

Machine learning can improve identification of random defects through artificial intelligence, but at a high training effort which is often not justified due to cost and time constraints. Additionally, machine learning systems are limited by the quality of images they are presented to analyze.

Human assembly inspection (left) and solar panel machine vision inspection (right).

By contrast, photometric inspection uses high-resolution light imaging and analysis techniques to identify defects missed by other methods. Photometry-based inspection systems excel at discerning defects even on complex assemblies and in low-contrast settings. They perform better than machine vision at spotting random defects, and better than human inspectors when it comes to consistency and repeatability.

Of all the various approaches, which is the best one to address your hard inspection challenge? How does photometry-based inspection work, and which applications benefit the most—and offer the most significant ROI—from use of this technology? To learn more, read the article, “What’s the optimal assembly verification method for tough inspection tasks?”.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List