Radiant Webinar Introduces First Software for Backlit Component Inspection that Combines Photometric Measurement and Machine Vision Defect Detection

REDMOND, Wash. – June 25, 2020 — Radiant Vision Systems, a leading provider of automated visual inspection systems for light sources and displays, announces that it will host a webinar to introduce its new VIP™ (Vision Inspection Pack) software—the first solution for backlit component inspection that combines the benefits of photometry for light and color measurement with machine vision for defect detection. The webinar, titled “The Ultimate Vision System for Backlit Components: Light, Color, and Defect Detection in One,” will be broadcast on Thursday, July 9, from 9:00 A.M. to 10:00 A.M. PDT (12:00 P.M. to 1:00 P.M. EDT). The webinar includes a 30-minute presentation, demonstration of VIP functionality within Radiant’s TrueTest™ Software interface, and a live audience Q&A session with Radiant’s technical presenters.

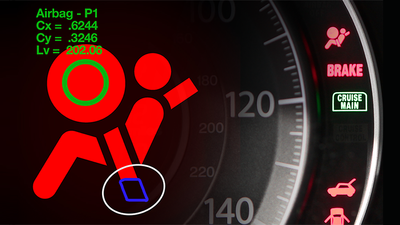

From illuminated automotive panels and avionics to backlit buttons and ports on electronics—light-emitting components require inspection to ensure quality according to specifications and standards. Backlit icons, shapes, and text are difficult to inspect not only because of their variety, but because their quality is determined by a combination of factors. Photometric properties must be measured to ensure accurate brightness, color, and uniformity of the illuminated area. Dimensional integrity must also be evaluated to ensure each area is free from defects and has the correct size, shape, and position. Photometric systems like spot meters excel at light and color measurement that reflects human visual perception, but these systems have historically lacked machine vision benefits like image analysis and registration functions that enable efficient measurement and defect detection within uniquely shaped regions. For this reason, evaluating backlit components has required multiple pieces of equipment or complex customization of machine vision software to ensure all inspection requirements are met.

Released on May 18, the VIP software license leverages photometric analyses for luminance and chromaticity from Radiant’s TrueTest Software platform and adds precise, responsive registration for unique shapes such as backlit icons, text, and freeform areas. By registering the exact contours of each illuminated area to create custom measurement regions, VIP enables defect detection to ensure regions are free from inclusions or exclusions caused by inaccurate laser etch or errors in overlays, filters, or other substrate layers. In high-throughput inspection applications, VIP provides an efficient solution for rapid registration of multiple shapes captured in a single measurement image. VIP quickly applies trained measurement regions to components inspected in series, regardless of component position or orientation, without requiring repeat registration or re-placement of measurement points-of-interest (POI).

Radiant technical presenters Matt Scholz, Automotive Business Leader, and Chris Williamson, Sales Engineer, host the upcoming webinar broadcast providing a conversational introduction to VIP software features with insights about optimizing the efficiency of backlit component testing. Attendees of the webinar will receive a demonstration of VIP software for backlit symbol inspection, showcasing its advantages over current systems for fast, hassle-free evaluation of illuminated components in lab or production-level applications. Attendees are invited to ask questions of the presenters during a live Q&A session at the end of the broadcast.

For information or to register for the webinar on July 9, visit www.RadiantVisionSystems.com.

About Radiant Vision Systems

Radiant Vision Systems works with world-class brands and manufacturers to deliver creative visual inspection solutions that improve quality, reduce costs, and increase customer satisfaction. Radiant’s legacy of technology innovation in photometric imaging and worldwide install base date back more than 25 years and address applications from consumer electronics to automotive manufacturing. Radiant Vision Systems product lines include TrueTest™ automated visual inspection software for quality control, and ProMetric® imaging colorimeters, photometers, and light source measurement systems. Radiant is headquartered in Redmond, Washington, USA, with strategic offices in California, Michigan, China, and South Korea. Radiant has been a part of Konica Minolta’s Sensing Business Unit since August 2015. For more information, visit www.RadiantVisionSystems.com.

Press Contact:

Shaina Warner

Creative Marketing Specialist

Radiant Vision Systems

+1 (425) 844-0152 x587

[email protected]