Achieving Uniformity in High-Resolution Displays

Display pixels are constantly changing, as both technology advancements and consumer demand drive improved picture quality. Smart devices, augmented and virtual reality headsets, and TV screens continue to offer higher and higher resolution and more vivid images.

The progression from LCD (liquid crystal display) technology toward OLED (organic light-emitting diode) and newer miniLEDs and microLEDs has resulted in smaller pixels, while the pursuit of contrast demands pixels with brighter brights and blacker blacks. This shift has provided consumers with improved visual experiences but has added production challenges for display manufacturers.

The Incredible Shrinking Pixel

Looking at different display panels in the photograph below, notice how the “dots” (display pixels) in the lower screen (A) are larger, and the black space between them is more pronounced. This display has lower pixel density, fewer pixels per inch (“PPI”), or a larger pixel pitch—these descriptions are roughly equivalent in meaning. The pixels are not very small or close together, so you can’t fit as many of them into a given area.

Examples of display panels with different pixel sizes, pixel pitches, and pixels per inch (PPI)—all of these factors impact display resolution.

The other displays show the pixel size and the space between the pixels shrinking as they progress backwards in the above image. The top/back-most panel (B) has the tiniest pixels, spaced the closest together (smallest pixel pitch), and therefore this display provides the highest PPI and the highest resolution.

Newer display types such as OLED and microLED are emissive technologies, meaning that each pixel is independently powered and emits its own light. This can result in wide variations in brightness and color from pixel to pixel, presenting a quality challenge for manufacturers. Each pixel needs to be measured individually for performance, whether used in a direct-view display or viewed through filter such as a quantum dot layer.

OLED television pixels measuring <10 micrometers each.

At the highest resolution levels provided by tiny pixels such as microLEDs, it can be difficult or impossible for the naked eye to discern individual pixels or subpixels. But variations in brightness (luminance) or chromaticity (color) from pixel to pixel are discernable to human viewers, marring screen and image uniformity.

To ensure the visual quality of these displays, therefore, a metrology solution must be able to measure a display as it is perceived by the human eye. But it’s not enough to just identify uniformity defects—a system also must be able to distinguish each individual micro-sized pixel element. Only by quantifying pixel and subpixel variations in luminance and chromaticity can a correction factor be calculated and applied to restore screen appearance. Once a display device is corrected in production, the manufacturer can now send it to market, knowing it meets both consumer expectations and brand standards.

The Art and Science of Display Inspection & Correction

Radiant’s product development team is continuously working to engineer our systems to strike just the right balance of imaging detail and imaging speed to ensure accuracy and efficiency for display inspection. This means producing higher-resolution imaging systems and more advanced image processing methods to keep up with the increasing resolution of emerging displays. Our ProMetric® Imaging Photometers and Colorimeters are now offered with senor resolutions up to 61MP to enable users to inspect even the highest resolution displays with precision and accuracy.

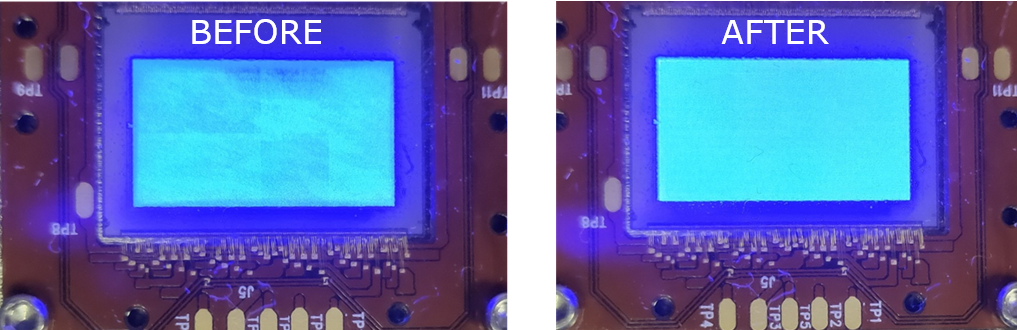

Pixel variation visible on microLED display (left) and uniform appearance after measurement and correction (right). (Image © Jasper Display)

Combined with Radiant’s TrueTest™ Software and using our patented spaced-pixel measurement method (US Patent 9,135,851) and/or fractional pixel measurement method (US Patent 10,971,044), manufacturers can inspect display pixels and subpixels while capturing an entire display in a single image for measurement at production-line speed. To learn more about how to achieve pixel uniformity for today’s high-resolution displays, read the article “Picture Perfect: Measuring and correcting pixels during production to ensure visual quality of OLED, miniLED, and microLED displays.”

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List