Correcting the Visual Quality of MicroLED Displays for Efficient Production

MicroLEDs continue to demonstrate their advantages for the display market as adoption of the technology is growing. These tiny light emitting diodes (LEDs) are individual elements that measure less than 100 µm—about /10th the width of a human hair—and some are as small as 3 µm. Their benefits over other display types include higher brightness, faster response times, and lower power consumption. MicroLEDs offer the potential for wider color gamut, higher contrast ratio, and deeper blacks than LCD (liquid crystal display) and OLED (organic light emitting diode) displays. MicroLEDs match OLED technology for response time and view-angle performance but exceed OLED in brightness and ruggedness while using far less power. These benefits are driving significant investment in the technology and pushing market forecast estimates up to 330 million units shipped by 2025.1

As the demand for higher and higher resolution continues, microLEDs are poised to be the next breakthrough technology in multiple segments of the display industry. Their small LED size and reduced pixel pitch yield clear and vivid images. They are particularly appealing for devices such as smart watches, head-up displays (HUD), and augmented reality (AR) displays where high luminance and resolution are particularly important for visual performance in small spaces, at close proximity to the eye, or under variable ambient lighting conditions.

Quality Challenge for Emissive Displays: Non-Uniformity

To realize the potential of microLED display technology, however, production challenges must be overcome. Ensuring the quality and uniformity of emissive displays such as OLED and microLED is challenging, since each diode is its own emitter, which is driven independently. A display made up of millions of microLEDs can exhibit wide variability in luminance and color.

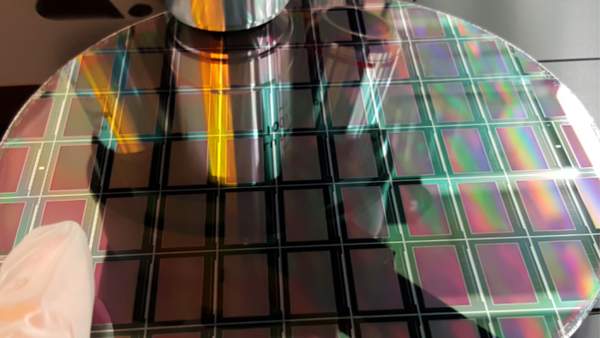

Backplane for monolithic microLED displays, from Plessy Semiconductor (Image Source).

This variability can cause an uneven appearance (non-uniform brightness or color across the display) that is discernable to a human viewer. A display with uniformity issues cannot be sold. Whether measuring microLEDs at the individual wafer level after deposition onto a substrate or once assembled onto the display backplane of a consumer device, microLED makers need a reliable inspection approach to measure and quantify microLED light and color output with precision to enable correction and thereby increase yields.

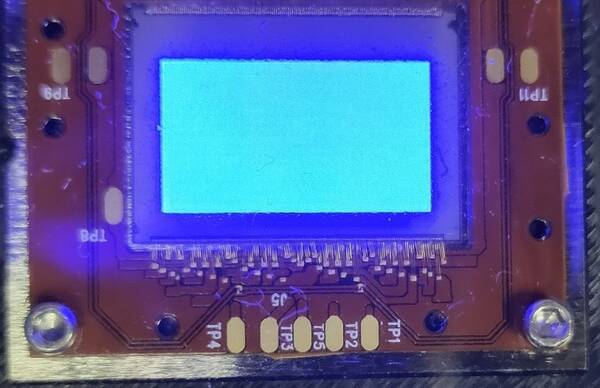

Variable luminance creates a non-uniform appearance in this 0.7” microLED panel (Full HD, 1920x1080) with LED size of 2µm and pixel pitch of 8µm. (Image © Jasper Display Corp.)

To ensure microLED device quality, a display metrology system must be able to accurately identify and measure the luminance (Lv) and chromaticity (CIE x,y or u’,v’) of each individual pixel and subpixel–that is, each diode. Radiant’s high-resolution, low-noise ProMetric® Imaging Photometers and Colorimeters are proven to measure microLEDs with precision, acquiring accurate and repeatable luminance and chromaticity values for each individual microLED beyond the capabilities of competitive measurement systems.

Once each pixel is isolated and quantified using image analysis tools in Radiant’s TrueTest™ automated visual inspection software, individual correction coefficients can be calculated and applied to each microLED ensure equivalent output and a uniform display appearance. Our image-based measurement systems provide the pixel-level precision and accuracy manufacturers need to inspect and correct microLED displays to achieve product quality, enabling production efficiency to meet market demands.

The same microLED display shown in the prior image now has uniform luminance after measurement and correction using a ProMetric® Y29 (29-megapixel imaging photometer) with Microscope Lens using TrueTest™ Software’s demura algorithms. (Image © Jasper Display Corp.)

Case Study: Jasper Display

Radiant Vision Systems is chosen by Jasper Display Corporation and other display innovators to improve the visual quality of emerging technologies like microLEDs. Used with Jasper Display’s MicroLED Starter Kit, Radiant’s advanced pixel measurement and uniformity correction (demura) solution helps manufacturers achieve their goals for efficient microLED display development while ensuring visually perfect display quality.

The ProMetric Y29 Imaging Photometer with Microscope Lens attachment has been used effectively to measure and correct luminance uniformity of microLED displays.

Watch a video case study with Jasper Display Corporation to learn about:

- Non-uniformity challenges in emissive displays like microLED, miniLED, and OLED

- The impact of pixel-level measurement and uniformity correction (demura) on display quality and production efficiency

- How Radiant’s high-resolution ProMetric® imaging system and software are applied for rapid and accurate demura of microLED microdisplays, like those produced using Jasper Display’s technology

CITATIONS

- MicroLED Displays, report from Yole Développement, February, 2017. Retrieved from: http://www.yole.fr/MicroLEDDisplays_Market.aspx

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List