Measuring and Correcting MicroLED Display Uniformity

MicroLEDs continue to demonstrate performance advantages for displays, ushering in a new generation of backlit and direct-view illumination technology. These inorganic emissive elements offer many benefits over other display technologies including high brightness and contrast, wide color gamut, longevity, and high pixel density. However, challenges associated with fabricating high-quality microLED panels must be addressed before viable mass production and commercialization can be achieved.

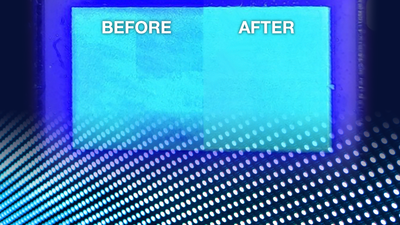

As individual emissive elements, microLEDs commonly exhibit luminance and color variations at the pixel level. These variations require each microLED to be measured and adjusted individually to ensure visual uniformity across the display. Thus, a measurement and correction system for microLED manufacture must be capable of precise quantification of the output of each emissive element (the individual LED or subpixel), with very low takt times to correct the high quantity of emitters in a single display and to support low-waste, high-volume production processes.

The white paper discusses:

- How microLED measurement and correction requirements can be satisfied using imaging colorimeters, applying unique equipment specifications, calibrations, and software functions

- Accurate microLED measurement and registration methods: “spaced pixel” (US Patent 9135851) and “fractional pixel” (US Patent 10971044)

- How Enhanced Color Calibration™ reinforces the chromaticity measurement accuracy of CIE-matched tristimulus filter imaging systems

- The benefits of various measurement and correction methods, demonstrated with test data and real-world application