Accelerating Automotive Lighting & Display Testing

Early Model-T Ford vehicles didn’t even have a speedometer (their top speed was just 35 mph), but soon after, dashboards began to include multiple gages, indicators, and vehicle controls. (Fun fact: the word ‘dashboard’ originates from horse-drawn wagons and carriages, where a board at the front protected passengers from mud that was ‘dashed’ up by the horses’ hooves.)

Dashboard of the 1925 Packard Touring. Photo Credit: Creative Commons (CC BY-SA 3.0 US)

The first automobile headlamps were introduced in the late 1880s and were powered by acetylene or oil. Electric-powered headlamps were first introduced to the market in 1898, but the first integrated ignition and electrical lighting system wasn’t developed until 1912 by General Motors.

Learn more about the history and development of headlights and the history of the automotive dashboard.

1965 AMC Rambler Classic with sealed headlamps (in use from 1940-1984, before the advent of composite headlamp assemblies with replaceable bulbs). Photo Credit: Christopher Ziemnowicz.

Modern Automotive Lighting & Displays

Since those early days, automotive lighting and displays have come a long way, and are essential to the functionality, safety, and driving experience of every vehicle. Designers and manufacturers have continued to push technology forward, and the cars of today and tomorrow may include innovative new features such as adaptive LED headlights, transparent head-up displays (HUDs) projected onto the windshield in the driver’s view, and integrated camera systems to give drivers a more complete view of areas surrounding the vehicle.

A range of dashboard instrumentation panels and displays found in today’s modern automobile.

Quality Assurance for the Cars of Today & Tomorrow

With technological advances, auto manufacturers are tasked with meeting ever-evolving regulations and industry standards for the safety and performance of virtually every element of a vehicle. To help designers and OEMs with R&D and production quality of critical vehicle systems, Radiant Vision Systems provides a complete portfolio of light & color measurement solutions that are enabling auto manufacturers to test and quantify virtually any self-illuminating element inside and outside the vehicle.

For a closer look at all the ways we’re helping OEMs ensure the quality, safety, and performance of vehicles, watch Radiant’s automotive solutions video:

In-Vehicle Displays

Embedded console, c-stack, and dashboard display screens are becoming more common for vehicle instrumentation, navigation, and entertainment. These displays must be able to perform under a wide range of ambient light conditions (from bright sunlight to nighttime). Automated visual inspection with Radiant ProMetric® Imaging Colorimeters and TrueTest™ software helps to detect quality issues during the design or production process, allowing manufacturers to identify potential process improvements, improve yield, and prevent flawed products from reaching customers. With a built-in library of tests for luminance, chromaticity, uniformity, contrast, mura, pixel defects, anti-glare “sparkle” effects, and image sticking, TrueTest is easily configured to meet specific needs, or to test against standard visual performance parameters such as the German Automotive Black Mura Standard.

Display View Angle Performance. View angle measurements are critical to automotive displays, which are commonly viewed off-axis from the driver or passenger point-of-view. Radiant’s FPD (flat panel display) Conoscope Lens provides angular resolution of 0.05 degrees per sensor pixel for high-precision measurement of luminance, radiance, angular contrast, CIE chromaticity coordinates, and correlated color temperature (CCT). Using Fourier optics, the lens captures every view angle up to ±70 degrees in a single image for analysis.

Radiant’s FPD Conoscope Lens mounts directly to a ProMetric Imaging Photometer or Colorimeter (either 16- or 29-megapixel sensor options)

A Radiant view angle measurement solution combines the FPD Conoscope Lens accessory and a ProMetric imager, which together reduce cost, form factor, and complexity compared to alternative goniometric measurement systems for angular measurement R&D applications. Because of its size and measurement efficiency, the FPD Conoscope Lens solution also enables in-line inspection of display view angle in production settings.

Measuring Sparkle of Anti-Glare Displays. Most in-vehicle displays are visually impacted by applied anti-glare films and coatings. Because automobile displays must be viewable in all types of ambient lighting conditions, anti-glare treatments help reduce reflective glare from sunlight or street lights. However, these anti-glare treatments can create their own interference. Called “sparkle”—a grainy appearance—this interference can impact the perceived quality of a display. Measuring perceived sparkle ensures that the user experience sets the standard for manufacture of AG displays.

Based on extensive studies conducted with leading OEMs, Radiant has defined a standard sparkle measurement method to acquire quantifiable data that consistently correlates to human visual perception of display quality. The Radiant Sparkle Measurement Method is the first to allow OEMs to set a numeric tolerance (for instance, maximum 2% measured sparkle) for displays supplied by their vendors, ensuring a consistent level of quality across all displays regardless of supplier, product, or time and location of testing. To lean more about this method, read the white paper “Method for Repeatable Measurement of Sparkle in Anti-Glare Displays.”

Headlamps & Exterior Lighting

Today's smart headlamps require a range of measurements to ensure proper illumination at all settings. To expedite this process, Radiant ProMetric imagers capture a wide spatial distribution of headlamp patterns on screens or walls, providing precise measurement of the light source’s illuminance distribution in a single measurement. Once measured, you can analyze a light assembly for multiple criteria, using the PM-HL™ Headlamp Evaluation Module. PM-HL provides evaluation of common ECE and US regulated test points, conversion to roadway illumination distribution, and more.

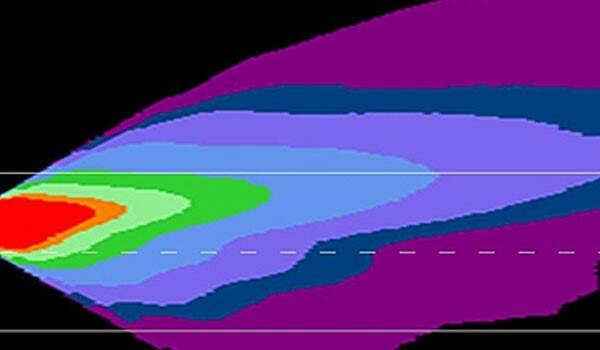

False color used to analyze the roadway distribution of a headlamp in the PM-HL software module.

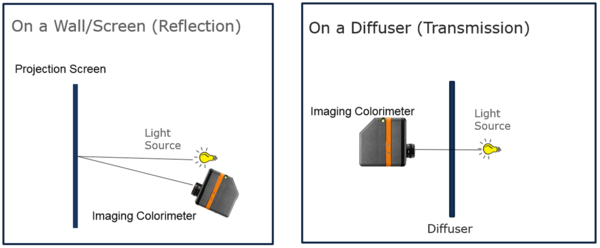

Lighting Assemblies. A method of establishing an illumination distribution—ideal for both labs and production-level quality control—is to measure the distribution of a source on a wall or Lambertian surface. The luminaire is mounted in such a way as to cast light directly onto a screen or diffuser, while an imaging colorimeter—driven by automated measurement control and analysis software (like PM-HL)—measures the luminous intensity and appearance of the beam.

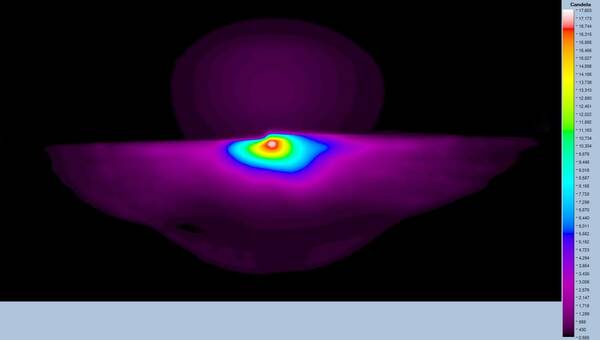

A Radiant ProMetric I Imaging Colorimeter provides fast, compact solution for far-field beam pattern measurement. The top image shows two possible setups for measurement of light source distribution a surface, where the imaging colorimeter measures the luminous intensity of the distribution. The image at the bottom shows the distribution pattern of a headlamp in false color in PM-HL™ Headlamp Evaluation Software.

Small Light Sources. Small light sources, such as single LEDs, may be characterized by a near-field model for use in optical design applications. To create this model, a precision goniometric system (SIG-400 Source Imaging Goniometer®) with a ProMetric Imaging Colorimeter takes measurements of luminance and color of the light source from multiple viewing angles. The measurement output is a Radiant Source Model™ (RSM) file that describes the near-field luminance distribution around the source. This RSM is supported by all major optical/illumination design software packages, and is converted to a ray set using Radiant ProSource® Software. These ray sets support optical design, and allow you to extrapolate a near-field model into a far-field model.

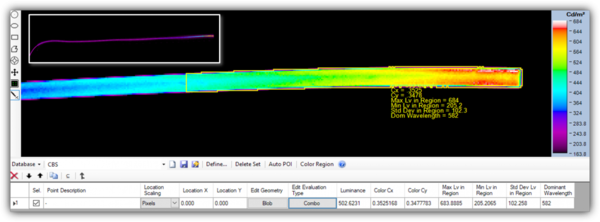

LED Lighting. Quality control for LED headlamps, taillights, and decorative light strips can be readily addressed with a ProMetric Imaging Colorimeter and Radiant software. You can determine luminous intensity distribution (in TrueTest only), measure uniformity of luminance and color along a path (such as a LED pipe), and detect failed LEDs in a cluster. ProMetric and TrueTest software even allow you to draw ROI (regions of interest) on a measurement image to evaluate lighting components of any shape or size.

Automotive headlamp assembly with LED light strip.

Measuring light strips and LED pipes for luminance, chromaticity, uniformity, yellowing and color change (top), and for intensity, D intensity, chromaticity, and D chromaticity (bottom) in TrueTest software.

Head-up Displays (HUDs)

HUDs pose unique measurement challenges for manufacturers. ProMetric Imaging Photometers and Colorimeters feature an electronically controlled lens that is highly effective at identifying and focusing on an image projected into infinity. The TT-HUD™ module of our TrueTest analysis software provides accurate luminance and chromaticity measurements at any working distance, and can test in nighttime, normal, and daytime settings to ensure consistent visibility of digital projections in ambient settings. High-resolution ProMetric cameras and software can be integrated with HUD systems to enable fully automated testing, with API to control test images and analyses in sequence from contrast, warping, ghosting, MTF, among other tests.

Interior Lighting and Instrumentation

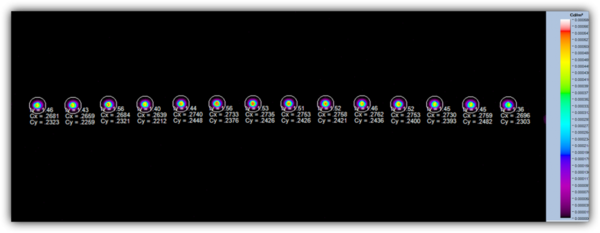

Instrument Clusters, Controls, Tell-Tales & Indicators. A ProMetric Imaging Colorimeter with ProMetric Software provides a simple and accurate solution for testing illuminated characters. The software features a powerful tool (Auto-POI, or Automatic Points-of-Interest) that allows users to automatically select points of interest based on color and luminance values (Lv and CIE x,y thresholds). You can then run calculations on a single character, or a group of like-characters, to ensure accuracy within or between symbols regardless of location, shape, size, or color. The Auto-POI system provides comprehensive data through ProMetric Software, including average luminance across characters, points of minimum and maximum luminance, color value, and dominant wavelength.

Auto-POI can be applied to any backlit symbols, including buttons and symbols on center stacks and other areas of the vehicle interior. For backlit modules, a combination of measurements can be applied on a single image to evaluate symbols using Auto-POI, as well as other backlit modules like halos or light strips around controls, hubs, or panel edges.

Automotive dashboard with lit gages and indicators (left) and in-vehicle backlit controls and decorative modules (right).

Using Auto-POI, manufacturers can easily measure and inspect multiple sets of symbols simultaneously within a wide-area image, without drawing static POI, which depend on fixed spatial tolerances.

Near-IR Sensing for Security, Safety, and Multi-Modal Control

New 3D sensing applications such as facial recognition, gesture recognition, and eye tracking use near-infrared (NIR) wavelengths of light. Because these wavelengths are invisible to the human eye, it’s imperative to ensure the safety of NIR emitters. Radiant’s NIR Intensity Lens solution provides complete evaluation of “flood” sources and dot patterns used by these systems to sense driver presence, awareness, and commands.

Camera Monitor Systems (CMS)

Electronic-display-based camera monitor systems (CMS) are starting to replace mirrors for viewing external vehicle scenes. Adopted by several countries, standard ISO 16505:20151 and UN Regulation No.46 are the first to permit the legally-required mirrors in passenger and commercial vehicles to be replaced by CMS. But CMS systems must pass tests to evaluate the visual performance of the display for mapping the real-world scene captured outside the vehicle.

Radiant ProMetric Imaging Colorimeters and Photometers paired with TrueTest Software provide a solution for CMS display testing that includes advantages for testing efficiency (performing all display measurements through a single solution), CIE-matched color evaluation, high-resolution imaging for testing MTF at required distances, angular performance measurement for uniformity at various viewing directions (using the Radiant FPD Conoscope Lens), and a complete CMS software test suite.

Rear-view backup camera, just one type of CMS being introduced into vehicles.

These Radiant solutions are helping to ensure the best performance, driver experience, and safety of vehicles of today and tomorrow. Need a measurement solution for the lab or in production quality control? Radiant has an Automotive Solutions Team that can help you find a complete system to accelerate your project.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List