Efficient & Accurate Measurement for ADB and Advanced Headlights

With the November 2021 passage of the federal infrastructure bill, adaptive headlights have finally been approved for use in the United States. This is big news for automakers—and a big advancement for the safety of everyone on the nation’s roads at night, where more than 40% of car accidents and fatalities occur despite 60% less traffic.1

Adaptive driving beam (ADB) headlights use sensor input to automatically adjust beam brightness, angle, and shape in response to changing driving conditions. If you’re driving at night with high beams on, the headlamps will quickly adjust when your vehicle senses another car to avoid shining into the eyes of the other driver. For example, Magna Lighting’s “glare-free” high beams can adjust for oncoming cars, for cars ahead in the same lane, or for both at once, and spotlight traffic signs as well.

Magna’s INVISION™ adaptive driving beam system. WATCH the video.

ADB headlamps have already been in use in Europe, Canada, Japan, and other locales for several years. Outdated regulations had kept them out of the US, despite a clear case for improved road safety. Research studies support the benefit ADB headlights offer.

The rapid response of today’s ADB technologies enables drivers to use their high beams as a default setting at night, increasing visibility over the low beams that US drivers use a majority of the time—64% of US drivers said they do not regularly use high beams.2 One US study found a 28% increase3 in forward illumination with high beams, while another study found that roadway lighting is increased as much as 86% overall4 when vehicles use ADB headlamps.

Volkswagen’s IQ.Light LED matrix headlight, developed together with German automobile supplier HELLA (Image © Volkswagen)

How Do ADB Headlights Work?

An essential element of any ADB system are cameras and/or sensors on the vehicle that monitor the surrounding environment, identifying other vehicles and objects and weather/lighting conditions on the road. The headlamps can be made with halogen, laser, or LED light sources. In some cases, light changes are controlled with shutters; most new ADB systems use an LED matrix design. As one example, Audi has designed its LED matrix headlight system featuring eight vertical “fingers” of light, with each finger able to switch on or off independently.6

Demonstrating the adaptability of Audi A4 LED matrix headlights. (Image: Source)

Another key component of ADB systems are reflective elements called digital light processing (DLP) chips. “DLPs include thousands of individually-controlled digital micromirror devices (DMDs) built atop a CMOS memory cell.”5 Sophisticated—yet tiny—computers control and coordinate all the elements of the system.

Demonstration of BWM’s ADB headlamps, called Selective Beam lights.

Regulatory Requirements

Any type of headlamp—traditional or ADB—must meet a range of industry standards in different regions. The US and Canada follow Department of Transportation (DOT) federal standards for headlight visibility, durability, and reliability.

In other geographies, standards created by The United Nations Economic Commission for Europe (ECE) have been adopted. The Society of Automotive Engineers (SAE) International standards also guide requirements for headlight performance around the globe. As new headlight technologies emerge, they are all subject to acceptance by one or more of these standards bodies.

Headlamp Measurement Approaches

To provide the required performance and meet stringent industry standards and regulations, automakers and headlamp suppliers must carefully test these lights to measure their output and performance. Today's smart headlamps require multiple measurements to ensure that they provide the proper illumination at all settings. One traditional measurement method used in the headlamp industry is goniometric measurement.

A goniometer is a piece of equipment that rotates a light source (such as an LED or headlamp) around a fixed horizontal axis, while a detector (such as a photometer) captures measurements from every angle in the rotation, compiling enough data to characterize the full distribution of the light. By taking thousands of individual measurements, a goniometric system is extremely accurate. However, the process is slow, taking hours for a full measurement scan.

In today’s dynamic headlamp market, newer technologies such as LEDs, microLEDs and ADB must be tested across a variety of parameters. Development and innovation is happening at a rapid pace, which requires a more flexible and timely measurement method.

Reduce Measurement Time from Hours to Seconds—and Maintain Accuracy

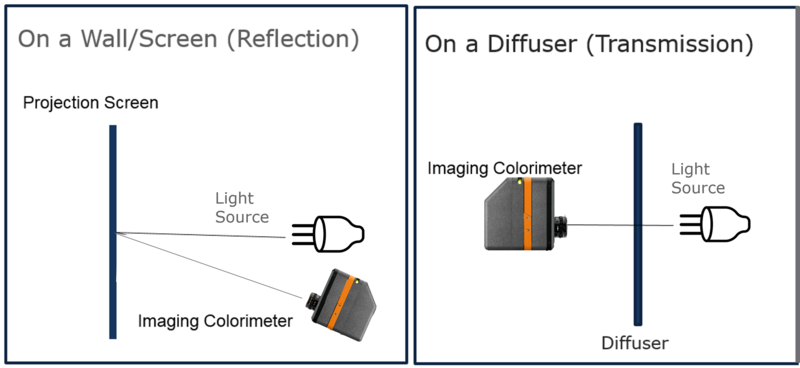

A different approach for evaluating headlamp performance is to project the light source onto a prepared flat surface (a wall or a diffuser), where a detector (such as a camera) measures the beam pattern. In the product R&D process, headlamp engineers make multiple adjustments and changes to product designs to achieve optimal performance.

Goniometric measurements are time-consuming to run, especially to assess every small design change, so the wall projection method provides a faster measurement option. Some companies have used machine vision cameras to quickly assess beam pattern data. While this method is much faster than goniometric measurement, machine vision systems cannot measure absolute luminance and chromaticity values. Compared to goniometric systems, machine vision systems have a margin of error typically around 20%.

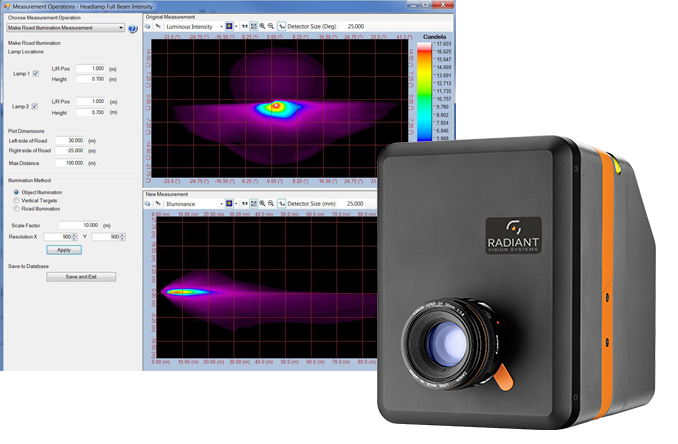

There is a better option that offers lighting engineers both speed and accuracy: using an imaging colorimeter in place of a machine vision camera to measure a projected light source. ProMetric® I-Series Imaging Colorimeters provide rapid measurement (a two-second takt time), while rivaling the accuracy of goniometric systems with only a 5% margin of error. This accuracy has been verified by correlation studies.

Projecting a light source for faster measurement of beam pattern distribution using a ProMetric® I-Series Imaging Colorimeter.

This approach enables manufacturers to rapidly iterate product designs. Multiple user-defined criteria can be applied for headlamp assembly testing using Radiant’s PM-HL™ Headlamp Evaluation Module. PM-HL functions include:

- Light source illuminance distribution measurement

- Evaluation of ECE and SAE Regulation test points

- Evaluation of custom test points

- Evaluation of beam pattern cut-off gradients

- Conversion to luminous intensity distribution

- Conversion to roadway illumination distribution

- Data analysis functions, including bitmaps, isoplots, and cross-sections

ProMetric I-Series Imaging Colorimeter with images of a beam distribution (shown in false-color scale) in PM-HL Software.

Customer Success Story: Magna International

One leading automotive lighting company, Magna Lighting, used goniometric systems for years, although measurement scan times were long. Magna needs to share data between their North American sites, with vendors, with Magna International colleagues in Europe, and with OEM customers. Each time they ran a scan, it required setting up the goniometer, running the test, verifying, and then exporting large data sets.

Magna Lighting’s DL-Optic ™ Headlamp (top) combines multiple high-powered 1x1 LEDs with injection-molded precision lenses. Magna's ECOLED projector-and reflector-based fog lamps (bottom). (Images © Magna Lighting)

Magna acquired a ProMetric system to measure luminance and other lighting data off a wall projection. The solution requires only a small lab footprint, enabling them to set up a dedicated 2D measurement station. By maintaining the same fixturing from measurement to measurement, there is no need to change the camera calibration. This enabled Magna to run beam pattern distribution measurements in rapid sequence. They were able to achieve weeks’ worth of testing in a single day.

For more information about automotive lighting measurement with Radiant imaging photometers and colorimeters, watch the webinar “Measurement Solutions for Interior and Exterior Lighting” and read the How-To Guide “Using Points of Interest to Meet International Headlamp Standards.”

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List