Microdisplays: Small Screens with Big Potential

Despite what their name might suggest, microdisplays are not necessarily microscopic—but they are pretty tiny. For example, at 2018 SID Display Week, BOE showed off a microdisplay screen that’s smaller than a penny:

Typically a microdisplay is less than two inches diagonal (approx. 5 cm). First introduced commercially in the late 1990s,1 they’re commonly used for rear-projection TVs, head-mounted displays, and digital cameras. In recent years, devices like smart watches have taken advantage of the high resolution and low power consumption of these displays. Microdisplays are expected to proliferate, with the global market projected at 20% compound annual growth rate (CAGR) through 2022.2 One of the trends driving this growth will be the increasing adoption of near-eye displays and augmented reality devices such as head-mounted displays (HMDs), head-up displays (HUDs), and electronic view finders (EVFs).

Sony’s Android Smartphone Remote with Microdisplay

Microdisplay Types

There are two main categories of microdisplays:

- Projection – A highly magnified image of the microdisplay is projected onto a surface. Types of projection microdisplays include rear-projection TVs and compact data projectors.

- Near-to-eye displays (NEDs) – The microdisplay consists of a highly magnified virtual image viewed through an eyepiece (such as a virtual reality headset or camcorder viewfinder). These displays are increasingly being used in HMDs and HUDs, especially in the military and medical industries.

Military helmet-mounted display.

Both types of microdisplays offer significant advantages over conventional direct-view displays such as flat-panel LCDs. Microdisplay advantages include:

- Ablility to produce a large image from a very small, lightweight source display unit—making them easy to integrate into space-constrained technology, such as wearables.

- Large pixel capacity, producing high resolution and clarity.

- Greater power-efficiency as compared to other display types.

The higher the resolution and lower the power consumption, the better quality the microdisplay. New advancements in this technology have enabled development of high-definition and ultra-high-definition microdisplays that provide an even better viewing experience. The challenge for microdisplay makers, however, has been relatively high production costs. Continuing R&D and technology advancements are now showing improvement in this area.

Microdisplay Technologies

Microdisplays can be made from a range of display technologies, including:

- Liquid Crystal On-Silicon (LCoS)

- Liquid Crystal Displays (LCD)

- Digital Micromirror Devices (DMD)

- Digital Light Processing (DLP)

And, more recently:

- MicroLED (Light Emitting Diode)

- Organic Light Emitting Diode (OLED)

- Holographic displays

LCD has dominated the microdisplay market in recent years.2 LCD technology offers high brightness, relatively low cost, and a relatively simple manufacturing process. Using LCDs, device manufacturers have been able to reduce the size of microdisplay components over time. LCD displays are currently being used in some HMDs, HUDs, EVFs, and thermal-imaging glasses and wearables.

LCoS displays are favored by some microdisplay developers for their ultra-high brightness and contrast, energy and heating efficiency, and elimination of the “screen door effect" that can sometimes plague magnified or near-eye displays. Screen door effect is another term for fixed-pattern image noise. It occurs when an image is magnified to the point where the spaces separating pixels or sub-pixels are visible, creating an effect of looking through a fine mesh—or screen door—at the image.

An example of the screen door effect, which occurs when a display is magnified or viewed up close, such that the space between pixels is visible. Photo: Creative Commons Attribution-Share Alike 4.0 International license.

Relatively new technology being explored by some microdisplay makers is OLED/microLED, which offers several advantages:

- Self-emitted light—there's no need for an "external" illumination (or backlight)

- A larger color gamut

- Wide viewing angles

- Better contrast

- Faster refresh rate

- Lower power consumption (this depends on the image shown)

- Wide operation temperature range

OLED microdisplay (Photo by Road to VR).

OLED microdisplays do have some disadvantages, however:

- Relatively lower lifetime and burn-in

- Lower brightness (although this is improving to the point where OLED microdisplays are actually very bright)

- Limited suppliers, limited volume and selection, higher price—making them a somewhat "immature" technology. 3

Time will tell which technologies turn out to be the best fit for various microdisplay applications.

Ensuring Microdisplay Quality

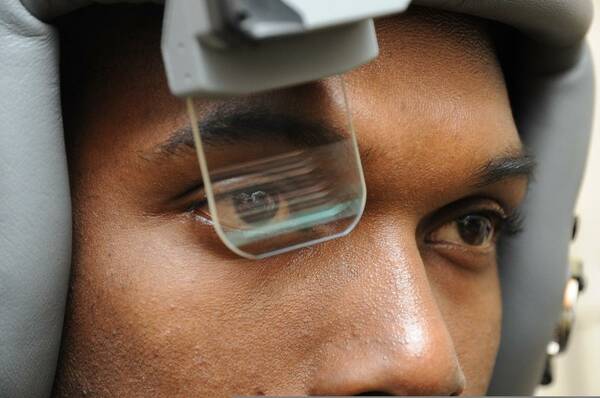

High-resolution displays provide sharp detail and clarity. But the viewing experience can be marred by quality issues like lack of uniformity and defects in the display. While potentially unnoticeable in large-format screens, dead pixels in a microdisplay are magnified—either through projection enlargement or due to the close proximity of the viewer’s eye. For microdisplay device manufacturers, ensuring perfect display quality is integral to device performance, and essential for maintaining customer satisfaction and brand reputation.

Radiant has developed imaging systems that can measure displays and identify defects down to the pixel and sub-pixel level. Our ProMetric® imaging photometers and colorimeters excel at discerning precise light and color variations and ensuring quality of LCD and OLED displays, at sizes from micro to large-scale. We also offer a unique AR/VR lens specially designed for efficient and accurate measurement of NED device performance, capturing the full field of view of the user from within a NED headset.

Radiant’s AR/VR Lens with Prometric imaging photometer simulates the size, position, and field of view of the human eye to measure the performance of displays integrated into virtual (VR), mixed (MR), and augmented reality (AR) headsets.

The future of displays may be micro, but the need for effective quality testing solutions is and will continue to be major.

Learn more about measurement and correction of OLED displays in this article published by Global LEDs/OLEDs on September 1: How to Use Colorimeters to Improve OLED Display Testing Efficiency and Yields.

Learn more about near-eye display measurement in the Radiant Webinar: Replicating Human Vision for Accurate Testing of AR/VR Displays.

FOOTNOTES:

l "Microdisplays” on Techopedia, https://www.techopedia.com/definition/23572/microdisplay, accessed 8/20/18

2 Global Micro Displays Market By Technology (LCD, DLP, LCOS & OLED), By Type (Projection Vs. Near-to-Eye), By End User (Consumer Electronics, Military & Defense, Automotive & Others), By Region, Competition Forecast & Opportunities, 2012 – 2022”. January 2018, Report Buyer. https://www.reportbuyer.com/product/5264930/global-micro-displays-market-competition-forecast-and-opportunities-2012-2022.html

3 "OLED Microdisplays: introduction and market status," on https://www.oled-info.com/oled-microdisplays, accessed 9/4/18

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List