MicroLEDs Gather Speed in the Automotive Industry

Since the 1980s when touchscreen displays first started appearing in automobiles, the industry has continued to expand display panel integration into dashboards and other locations of the car interior. LCDs have been the predominant automotive screen technology since the beginning, until the emergence of OLED display technology offered the prospect of higher brightness for improved visibility in all ambient light conditions.

Additionally, the flexibility of OLED panels opened up new design possibilities with curved displays, enabling manufacturers to get more creative and integrate displays into a wider variety of spaces in the automobile. But OLED displays have had issues meeting the durability requirements of an automotive environment. Vehicle components are subjected to extremes in terms of temperature, direct sunlight, humidity, and vibration. Thus, OLED hasn’t yet made significant inroads, and LCDs remain the mainstream display of the automotive industry.

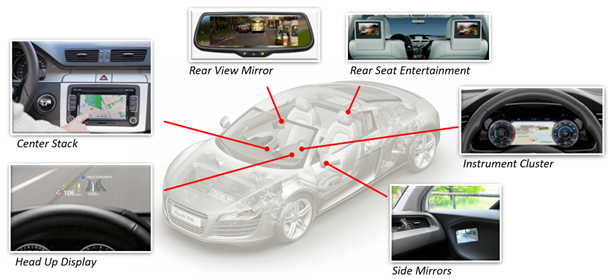

A few of the potential locations for displays within an automobile include the dashboard, center stack, HUD, passenger entertainment displays, camera mirror system (CMS) integrations, and more.

Benefits of MicroLEDs for Automotive Applications

MicroLED displays, however, promise to deliver the improved brightness and flexibility of OLED, with greater reliability, exciting the interest of automakers. MicroLEDs offer multiple advantages for automotive display applications, including:

- High luminance and contrast

- High pixel density (pixels per inch, or PPI)

- Wide color gamut

- Flexibility

- Low power usage

- Stability at a wide range of operating temperatures

In fact, microLED displays are expected to reach commercialization in the automotive industry as soon as 2022-20231. For example, AUO’s new microLED TFT automotive displays include a 9.4” curved screen built on a flexible plastic LTPS backplane:

MicroLEDs are expected to catch on more quickly in the automotive industry than in the consumer mass market. High fabrication costs remain a challenge for consumer products, limiting microLED products thus far to high-end devices in the television, AR/VR headset, and smartwatch categories. As one of many components of an automobile, however, microLED displays add a relatively small incremental cost that can be more easily absorbed into the vehicle price.

MicroLEDs Enable Next Generation Automotive HUD

MicroLED technology is particularly attractive for the new class of automotive head-up displays (HUDs), “since it is the only display technology which could offer the high enough brightness to yield the contrast necessary to clearly see an image against a bright sun-lit background (including sun shining right through the windshield) and wide operation temperatures to withstand weather swings from bitter cold in winters to scorching heat in summers.”2

HUDs project semi-transparent virtual images into a driver’s field of view, allowing the driver to track key information like speed and navigation while keeping their eyes on the road. These images can be projected onto reflective film applied to the interior surface of a car’s windshield or onto a transparent display screen (combiner) installed on the dashboard.

Windshield HUDs are quickly replacing combiners, particularly with the development of AR-HUD (augmented-reality-HUD) systems. AR HUDs project across wider fields of view—using more of the windshield for the display—and at a greater range of virtual image distances, enabling images to integrate more dynamically with objects in the exterior environment.3

Plessy demonstrates a microLED HUD display.

With the automotive HUD market projected to grow at a 22% CAGR, reaching $5.7 billion globally by 2030,4 microLED displays have a bright future in the automotive industry.

MicroLED Quality Challenge: Uniformity

To achieve market success, however, will require that product manufacturers deliver the quality that consumers expect. MicroLEDs are individual emitters—each driven independently to produce its own light—which enables the wide color gamut and contrast that appeals to automakers. But this independence also means that microLEDs can be subject to a wide range of variability in brightness and color, resulting in a non-uniform appearance that can render the displays unusable (unsalable).

Variability is compounded because each microLED is typically a monochromatic subpixel (red, green, or blue) whose output is combined with other subpixels to produce the overall brightness and color of a single display pixel. This variability at the subpixel and pixel level manifests as a non-uniform appearance across the display, resulting in low yield of acceptable displays, rejection of expensive components, or costly rework.

For microLED display devices to achieve mass-market success, they must deliver a flawless consumer experience, including uniform brightness and color appearance. Defects, variations in luminance or chromaticity, dead pixels, and other irregularities can quickly deflate buyer satisfaction and hurt brand reputation. If these issues cannot be addressed and corrected at the component level, low yields and high production costs will impede the viability of microLED display technologies for mass production and market commercialization.

To address this challenge, microLED manufacturers must have rigorous inspection process. Because microLEDs can be driven independently, manufacturers can also employ systems that apply corrections to each emitter, improving display appearance without rework. One solution chosen by leading microLED innovators is an inspection system from Radiant Vision Systems that enables measurement and correction at the pixel and subpixel level. With uniformity issues addressed in production, Radiant helps these manufacturers ensure quality products while increasing yields.

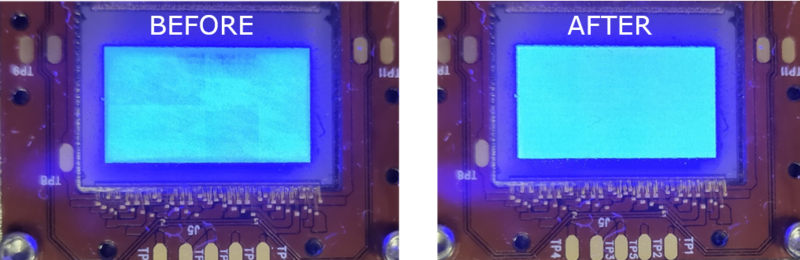

A microLED display before correction (left), and after the correction process—called demura—has been applied (right), resulting in a uniform appearance. (Images © Jasper Display)

Radiant MicroLED Inspection Solutions

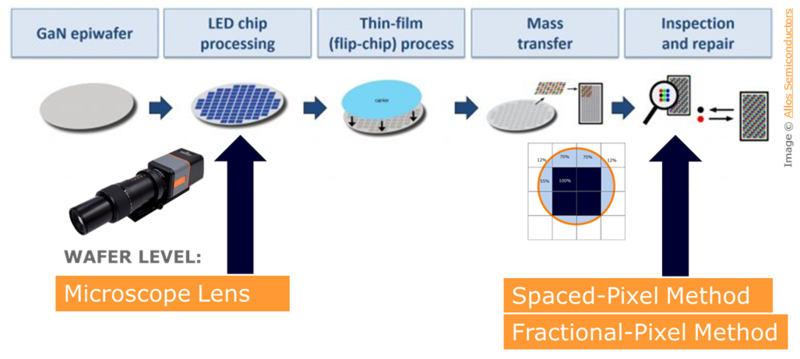

Radiant offers a range of solutions and methods to address imaging precision at critical points in the microLED fabrication process. To provide wafer-level inspection of microLED chips, a ProMetric® Imaging Photometer or Colorimeter and TrueTest™ Software can be used with our Microscope Lens to magnify microLED subpixels at extreme detail in a measurement image.

For panel-level inspection, Radiant has developed two methods that have been proven to significantly improve an imaging system’s ability to isolate and measure increasingly small subpixels in increasingly high-resolution displays: a “spaced pixel” method and a “fractional pixel” method. Both methods rely on proprietary algorithms and analysis techniques applied via TrueTest.

Radiant provides unique hardware and software solutions for pixel- and subpixel-level inspection at each stage of quality inspection during the microLED fabrication process, at the wafer stage inspecting individual chips, and at the panel stage following mass transfer and assembly.

For more information about these microLED measurement systems and methods, read the whitepaper Measuring and Correcting MicroLED Display Uniformity. Topics include:

- How microLED measurement and correction requirements can be satisfied using imaging colorimeters, applying unique equipment specifications, calibrations, and software functions

- Accurate microLED measurement and registration methods: “spaced pixel” and “fractional pixel”

- How Enhanced Color Calibration™ reinforces the chromaticity measurement accuracy of CIE-matched tristimulus filter imaging systems

- The benefits of various measurement and correction methods, demonstrated with test data and real-world application

CITATIONS

- Han, S. and Huang, A., “Automotive micro LED display commercialization expected in 2-3 years”, Digitimes, April 23, 2020.

- MicroLED Market Opportunities 2018-2027, N-Tech Research, July 10, 2018

- Chen, Y., “HUDs with LED and Laser Light to Become a Trend in Automotive Application”, LEDinside, October 25, 2019.

- Automotive Head-up Display Market, Transparency Market Research, July 13, 2020.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List