OLED on the Cutting Edge

Transparent displays? Flexible and foldable phones? Stick-on displays? These may sound like the displays of the future, but already Organic Light Emitting Diodes (OLEDs) are providing the foundation for these next-generation display products. Some of them are starting to become available already, and others could be coming sooner than you might think.

Prototype transparent OLED display from Samsung. Image: Maruizio Pesce, CCA Generic 2.0 License

LEDs (light-emitting diodes) give off light when electrons are transmitted through a specially treated ("doped") solid inorganic material. An OLED is simply an LED where the light is produced ("emitted") by organic molecules. The world’s first working OLED was developed in 1987, by chemists Ching W. Tang and Steven Van Slyke at Eastman Kodak. Since then OLED technology has grown to be more than a $25 billion industry,1 with sales projected to reach $48 billion by 2023.2

This growth is fueled by the adoption of OLEDs for myriad display applications including:

- Cellphones, which account for roughly 80% of the market1

- Tablets and computers

- Televisions, which account for roughly 16% of the market1

- Automotive displays

- Wearable AR/VR products for both entertainment and industrial uses

- Gaming consoles

- Cameras

- Appliances in other consumer electronics, as more and more “smart” devices integrate display screens as a primary user interface.

Smart watch using OLED display pixels.

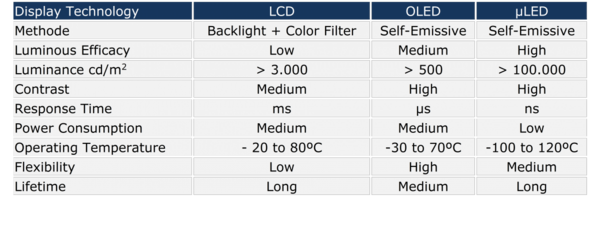

Credit goes to the folks at Coherent who compiled this useful chart comparing the performance of Liquid Crystal Displays (LDCs), OLED, and the newer Micro-LED (µLED) technology. Clearly the trend toward new display types is driven by several factors. The fact that technologies like OLED and Micro-LED offer increased physical flexibility, however, is an added benefit that can be leveraged for realizing completely new display integrations.

We’ve been seeing curved OLED television screens for a few years now; flexible and foldable displays for next-generation smart devices are already well along their way thanks to OLED and Micro-LED technologies. We may even see these products on the market in 2019. Recent advancements in the OLED arena include:

- Transparent OLED. Some OLED materials are transparent, making it possible to create transparent displays. OLED images can be formed on glass or other transparent surfaces, allowing users to view them while still being able to see through the display. Small (up to 2.4”) transparent displays have been on the market for several years already, and manufactures have now created large screen prototypes up to 55”. Learn more...

Planar discusses transparent OLED technology.

- Enhanced OLED Performance. Researchers at the Universitat Autonoma de Barcelona have been exloring the possibility of using ultra-stable film formation to improve the brightness and durability of OLEDs. Their recent study showed significant increases in efficiency and operational stability (> 15% for both parameters and all cases; significantly higher for individual samples) achieved for four different phosphorescent emitters. Read more...

- Stick-on OLED. Engineers in South Korea have devised a way to incorporate molybdenum disulfide (MoS2) transistors into bendable OLED displays. The result is a 7-micrometer-thick plastic sheet that can be adhered directly to human skin. Potential applications for this technology include super-thin smart watches. Read more about how they did it…

MoS2 flexible, stick-on OLED display.

Quality Control for OLED Displays

Today’s consumers of high-end, cutting-edge devices expect flawless appearance and performance right out of the package. For this reason, manufacturers need accurate, repeatable visual inspection regimens to ensure OLED optical performance. An inspection system must be able to detect even minute visual defects and prevent them from ending up in customer hands.

Radiant’s experience qualifying flat panel displays (FPDs)—including smart devices, tablets, televisions, and computers manufactured by the leading consumer electronics companies—has enabled us to develop the latest innovative optical measurement and correction solution for OLED screens. Algorithms and test methods that we have engineered to detect defects in FPD and large-format OLED screens also apply to smaller smartphone screens: measuring and qualifying issues like mura (blemishes), non-uniformity, pixel defects, and even brightness and color discrepancies at the subpixel level to characterize the independent emissions of OLED light-emitting elements.

These same test methods can be extended to measure the quality of flexible/foldable OLED screens. Radiant’s ProMetric® Imaging Colorimeter and TrueTest™ Software solution not only detects and quantifies OLED display defects and subpixel emissions, but can apply correction factors to ensure display uniformity across subpixels in a process called “demura”.

Learn more about “demura” and how this method is used to ensure the absolute uniformity of emissive display technologies like OLED and Micro-LED in our webinar “OLED Pixel Measurement and Correction".

CITATIONS:

- OLED Display Forecasts and Technologies 2019-2029: The Global Rise of Flexible and Foldable Displays, published September 2018 by IDTechEx. LINK

- OLED Market by Display Application (Smartphone, TV, Automotive, NTE), Panel Type (Rigid, Flexible), Technology, Size, Material (FMM RGB, WOLED), Lighting Application (General, Automotive), Panel Type, & Vertical, and Geography - Global Forecast to 2023, published by Markets & Markets, November 2018. LINK

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List