Radiant at 30 – Staff Stories: The Heavy Optics Club

Miniaturization has been a driving trend in electronics for decades. But once upon a time, there were some pretty large systems and components—from NASA’s entire room of mainframe computers in the 1960s, to Radiant’s own early Source Imaging Goniometer® (SIG) systems. Rick Albrecht, former Radiant Optical Engineer and inventor of the SIG, tells the story:

In the early days at Radiant (then called “Radiant Imaging”) most of the engineering involved writing software. A lot of the software was written to operate a calibrated CCD camera. However, the software guys felt the need to control something larger than a camera.

One of our engineers had a background in mechanical and optical equipment. One of the first large machines this M/O engineer designed was a Source Imaging Goniometer (SIG). The first sources tested with this system were 7 KW - 18 KW arc lamps, which required a large machine to hold the lamps for testing while a camera rotated around them to measure the light output at different angles.

In 1999 the second of the SIGs was designed and constructed, called the SIG-200. When fully assembled, this machine weighed 1400 pounds (635 kg); the frame alone was 1300 pounds (590 kg). This was the start of the Radiant “Heavy Optics Club.” To be a member you had to lift, or assist in lifting, an optical machine that weighed more than you did.

The SIG-200 being readied for transport.

The image above shows a SIG-200 and its shipping crate loaded onto the M/O engineer’s (home-built) trailer. The trailer was backed into the Radiant shop next to the welding area. After welding and painting was complete, a one-ton overhead crane was used to load the frame of the SIG-200 into the shipping crate on top of the trailer and was transported to the engineer’s home shop.

The trailer was backed under the deck, which had a heavy-duty beam attached with hand-cranked hoist. The SIG-200 was lifted from the trailer and attached to a rolling base. This next photo shows Radiant Imaging’s CEO operating the hand crank to raise the 1300-pound frame of the SIG-200. Tens of thousands of dollars’ worth of parts and labor is shown here hanging from that hoist.

Ron [Rykowski, founder and then-CEO] operating a hand-cranked hoist to lift the SIG out of the trailer and set it on its rolling base.

Ron (left) and Joel Diester (right) maneuvering the SIG-200.

If you ignore the 2000-pound (900 kg) capacity cable and the lifting yoke, you might think these two software engineers in the photo above were very strong to hold 1300 pounds of SIG. In a few moments the SIG was lowered onto its rolling stand and moved into the shop.

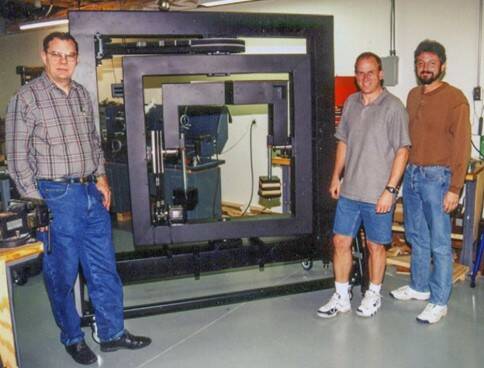

The first SIG-200 before the motors and electronics had been installed. Ron (second from right) and Joel (right) worked on the software while Rick (left) finished assembling the SIG.

Former Radiant employee Flint Jackson watches the SIG-300 being moved by forklift.

The next-generation SIG model we designed was the SIG-300, another example of heavy optics. The SIG-300 weighed in at 300 pounds (136 kg), but I don’t think that’s why it was call the SIG-300.

Over time all of upper management was part of the Heavy Optics Club. The optical table in the photo below weighs 1000 pounds (454 kg) and is on top of a 250-pound (113 kg) frame the engineer had specially fabricated.

Doug Kreysar [now Radiant’s CEO] stands by the 1000-lb optical table and its 250-lb rolling frame.

Later the “Advanced Heavy Optics Club” was formed. “Advanced” meant we needed to lift heavy optical machines and components more than 20-feet. When Radiant Imaging moved to a new building in Duvall, WA, in the late 1990s, there was no room in the small elevator for the SIG-200. Fortunately, there was a balcony three stories above the parking lot that was just big enough to “land” the SIG on.

The SIG-200 “flies” up to Radiant’s new office on the third floor.

After this office move, a new product specification was established: all equipment had to be designed to fit in the elevator either assembled or in parts.

Editor's Note: While it does have a smaller form factor (just 71 cm x 56 cm x 125 cm), today’s SIG-400 system weighs 130 kg (>286 pounds), so it is still possible to join the Heavy Optics Club, for anyone who’s interested….

Radiant’s current product, the SIG-400 Source Imaging Goniometer.

To learn more about the development and operation of the SIG systems, check out this blog post. To read more about Radiant’s history including additional staff stories, see candid photos, timelines, and more, visit our 30th Anniversary page.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List