How to Use Imaging Colorimeters to Correct OLED, MicroLED, and Other Emissive Displays for Improved Production Efficiency and Yields

Emissive OLED, microLED (μLED), and miniLED are emerging as the next wave of technology in the display market. This is exciting because these displays promise improved display performance and visual appearance with greater efficiency than other display technologies, thanks to their individually emissive pixel elements. As manufacturers work to launch commercially viable OLED and microLED displays, high costs due to manufacturing yield issues have hindered widespread technology adoption, most dramatically in large-format implementations, since they drive up consumer prices.

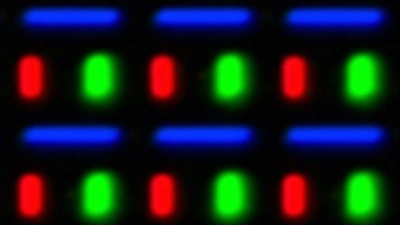

The application of imaging colorimeters improves OLED and microLED display production by ensuring visual quality of displays—measuring brightness and color uniformity at the pixel and subpixel level to correct poor quality displays and safeguard manufacturing investment. An imaging colorimeter system is one very important component in manufacturing processes that boosts efficiency and yields in display production, ensuring optimal price/performance.

In this White Paper you will learn about:

- Manufacturing challenges of OLED and microLED technology

- Applications of imaging colorimeters in emissive display measurement and manufacturing

- The process of "demura" for display measurement and correction

- How correcting emissive displays improves yield and supports market growth