Breaking the Mold in Automotive: Curved Displays

My blog a few weeks ago took a dive into the world of automotive freeform displays, and discussed how these novel shapes have given auto- and panel-makers the ability to freely design displays into any integration space.

Well, almost any space. While freeform displays break out of the traditional rectangular format to fit any flat frame or flat shape, vehicle interiors are a landscape of curves and contours. As displays take over more of the vehicle interior, designers are turning to emerging flexible display technologies to mold displays to any and all interior surfaces and further improve space-saving integration.

A New World of Flexible, Foldable Displays

Flexible displays are a major headline in consumer electronics news these days. The leading manufacturers of smart phones, tablets, TVs, and beyond are using the flexibility of emissive (no-backlight-required) display technologies like OLED, microLED, and others to innovate beyond flat, rigid panels.

This month, Samsung invited consumers to “reshape their future” with the release of its new Samsung Galaxy Fold smartphone—featuring a foldable AMOLED display screen that opens outward to reveal a tablet-sized display, and inward to collapse down to pocket size.

The newly released Samsung Galaxy Fold smartphone. (Source: Samsung.com)

Other flexible and foldable concepts are rampant, filling booths at all global consumer electronics and display tradeshows from CES in January to Display Week in May to Touch Taiwan in August. Applications range from the hottest trend—flexible smartphone and tablet displays—to more imaginative concepts like curved displays on vases, bespoke displays on three-dimensional packaging, and flexible displays on textiles.

A look at the range of curved display concepts by Visionox booth at this year’s Display Week 2019 in San Jose, CA. (Video source: Dave Haynes, sixteen-nine.net)

Tag, You’re It: The Automotive Industry Adopts Flexible Designs

Automotive human-machine interface (HMI) innovation tends to reflect the technical advances and expectations of the consumer electronics market—minus most of the wild concepts. The beauty of the automotive space is that there are so many practical applications for displays where benefits can be immediately realized. For example, displays may be the optimal HMI to replace what is already a wealth of analog components (buttons, knobs, gauges) within the vehicle. However, traditional rectangular and even flat-panel freeform displays limit the extent to which displays can be integrated into the vehicle design. Since automakers aren’t about to redesign the vehicle to accommodate the display, they need the display to accommodate the interior shapes of the vehicle in a way that best enhances operability and comfort for the driver.

With flexible display technology now providing the ability to match the dimensionality of vehicle interiors we may be headed toward an automotive display boom. Already several enticing concepts have been delivered by display makers, like these future displays below rendered by Flexenable.

Flexible display concepts that match the dimensionality of the A-pillar (left) and door frame (right) to enable seamless, space-saving integration that enhances visibility and operability. (Source: Flexenable)

At CES 2018, Samsung’s newest subsidiary HARMAN International showcased a digital cockpit concept with curved center-stack controls and a completely display-based dashboard. (Source: HARMAN)

A likely target for early curved display integration is in direct view of the driver. Displays that occupy the speedometer region or center stack of the vehicle—used to present critical information to the driver for monitoring vehicle performance, gauging speed and distance, and navigation—are on the rise. These displays greatly improve the accessibility of real-time and comprehensive data versus their analog counterparts, and with the added benefits of enhanced brightness, color, and contrast for better visibility in all lighting conditions.

Already, curved displays have entered production applications for integration into automotive dashboards. I highly recommend watching the video below from Continental Automotive Group on the evolution of the cockpit from analog to digital, and how they have optimized the 3D display molding process for their curved displays using plastic materials.

(Source: Continental Automotive Global)

Another production application, below, is touted as the “world’s first curved instrument cluster on the road.” Bosch innovated this small curved display to fit seamlessly into the speedometer region of the new digital cockpit for the 2019 Volkswagen Touareg.

A curved instrument panel display by Bosch manufactured for the 2019 Volkswagen Touareg, shown inside (left) and outside the vehicle (right). (Source: Bosch)

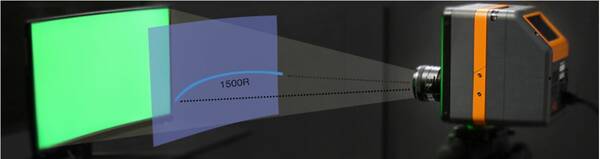

The Bosch display panel is specified at a 12.3-inch diagonal size with a 1,500-millimeter radius of curvature (also called 1500R in the curved-display world). This horizontal curve is a design benefit to both match the shape of the dashboard and elevate the vehicle’s sensor of luxury—and at the same time offers unique visualization benefits for the driver.

Benefits of Display Curvature for Visualization

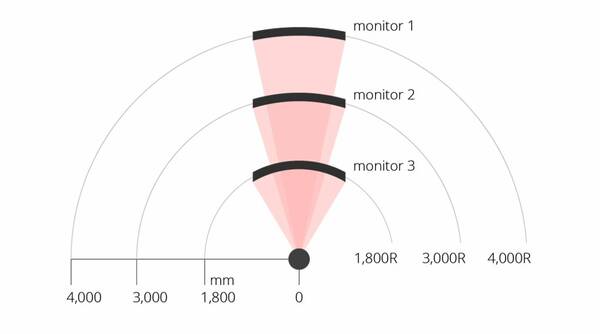

Studies on visualization of curved versus flat monitors have suggested that curved displays can reduce visual fatigue and improve viewer comfort. In their paper “Factors Associated with Visual Fatigue from Curved Monitor Use: A Prospective Study of Health Subjects,” Haeng Jin Lee and Seong Joon Kim outline the effect of display curvature (4000R, 3000R, 2000R, and 1000R) on twenty adults who performed various visual tasks using each display. During the study, eye movement and the participants’ subjective symptoms were measured. The ultimate finding was that “eye pain” (visual fatigue) was much greater for users after viewing a flat monitor versus a monitor with a 1000R curvature.1

An illustration of display curvatures as seen at a specific distance by a human viewer. (Source: Viewsonic)

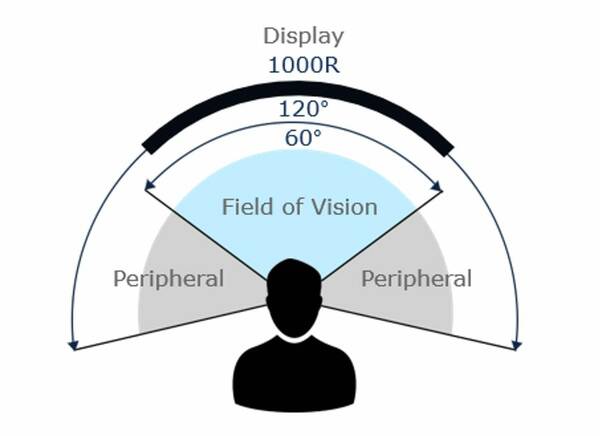

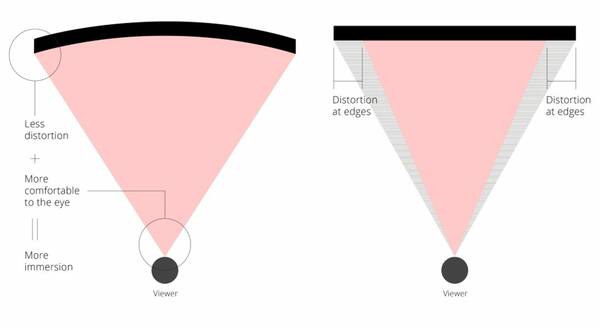

This study supports the general argument among panel makers that curved displays aid visualization because the radius of human peripheral vision closely matches a curvature of 1000R.2 Horizontal curvature of 1000R can reduce eye movement and distortion of elements at the display edges. It can also improve visual immersion, all of which are very important for drivers who have a very limited amount of time to glean information from the display while operating a vehicle.

An illustration of the typical human field of vision and extended peripheral vision compared to a display with 1000R horizontal curvature.

An illustration of how curved displays reduce visual distortion at the display edges when seen from a single point (i.e., the viewer’s location). (Source: Viewsonic)

These benefits give automakers a solid case for continuing to pursue curved displays, if an elevated aesthetic and design freedom weren’t enough. The remaining question is how to maintain objective quality standards for visual display performance now that displays are taking new shapes. Quantitative measurements are needed to ensure curved display quality meets all the same visual performance requirements as traditional displays, in terms of both vehicle functionality and user expectations. But—as many manufacturers know—automating the process of measurement along a curve has always been challenging for any vehicle display or surface.

The Challenge of Measuring Curved Displays

Flat panel displays (FPDs) have provided the foundation for display test methods for years. Display measurement equipment such as photometric imaging systems are designed to acquire luminance, contrast, uniformity, and other data in a single image across a flat, two-dimensional plane, matching the dimensionality of traditional FPDs. These displays are effectively measured from a single perpendicular angle to limit focus changes or view-angle effects, like changes to brightness, color, or contrast that may obscure defects when light is received at an angle through the various display layers.

However, measuring curved displays requires a new approach to account for changes along the curve. A single perpendicular measurement angle, a single measurement image, and a traditional analysis method may not be sufficient for ensuring the accuracy of data used for curved display evaluation.

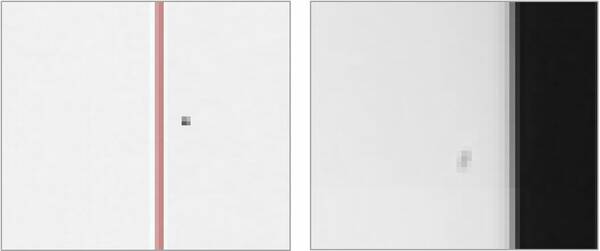

For example, the shape, size, and contrast of defects in images may appear to change depending on how far the imaging system deviates from a perpendicular position (a “normal” position in relation to the display surface). When the imaging system is aligned to a central point on a curved display, defects on the edges of the display may be distorted or fall out of focus.

These pixel defects below (cropped from a measurement image taken by an imaging photometer aligned to the center of a curved display) vary dramatically in terms of shape and contrast from the center to the edge of the display. If you were looking for small defects like these to qualify your curved display, you would likely set thresholds for the expected contrast or eccentricity (how far from “round” the defect shape is) of a pixel defect. However, your thresholds for detection might not catch the pixel defect on the edge because it doesn’t match the expected characteristics of a pixel defect. This could result in defects escaping your visual display test, based on the limitations of the traditional measurement method.

Comparison of pixel defects in a measurement image of a curved display, captured by an imaging system positioned perpendicular to the display center. From this angle, a pixel defect at the center of the display (left) appears more high contrast and round than the defect at the edge (right).

Display formats are changing, and measurement methods need to keep up. In light of this, engineers at Radiant have performed a series of lab-based studies to test the effectiveness of measurement methods and imaging system specifications for qualifying curved displays. The good news is that there are ways to reduce the kinds of effects we see like the pixel defect differences above. A combination of high-resolution imaging, a large depth of field (DOF) based on lens aperture settings, and creative combinations of imaging system positions and analysis methods can bring us closer to a very effective, efficient curved display measurement solution that requires minimal adaptation of traditional display test methods.

The Impact of Resolution

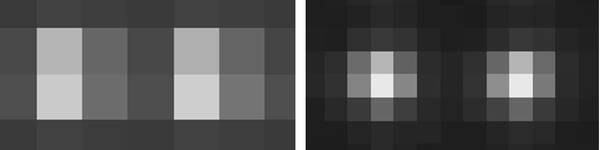

Increasing the resolution of an image-based measurement system adds photo-sensing elements (sensor pixels) to the measurement process, which enables the system to capture more precise details—more precise variations of light—within smaller spatial areas of the display.

Measurement images showing how detail in display pixels increases (in this case, illuminated pixels) as the resolution of the imaging system is increased (lower resolution image at left, higher resolution at right).

At the display-pixel level, increasing resolution increases the number of sensor pixels used to detect a defect. When a defect is captured using more sensor pixels, the tolerances used to detect defects can be made much more precise, eliminating false defects from being detected (like particles on the display that look similar to pixel defects) and enabling the system to capture all defects of an exact size.

The Impact of DOF

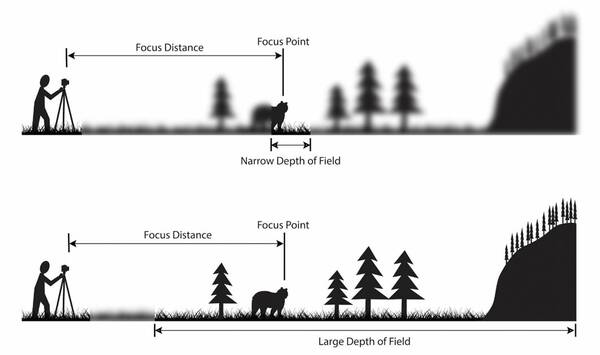

Increasing DOF (by restricting the aperture or F-stop of the imaging system lens) can increase the range of distances at which elements can be imaged in sharp focus.

An illustration of the impact of DOF when capturing images at a given focus distance. (Source: PhotographyLife)

DOF is a very important imaging system setting to consider for curved display measurement, because the curve of the display inevitably changes the focus distance of the display surface to the imaging system at a fixed position. For instance, when defects on the edge of a curved display fall out of focus for the imaging system—limiting defect contrast—increasing DOF brings these defects into focus and into uniform contrast with defects at the center of the curved display.

The Impact of Imaging System Position

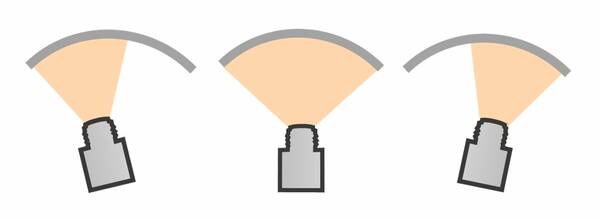

As noted above, defects are challenging to capture across curved displays because they can fall out of focus in images captured from a single position. This is because the imaging system is not able to capture all areas of the display at a “normal” (perpendicular) angle in a single image. One possible solution is to capture multiple images along the curve of the display for analysis, which not only increases the amount of visual performance data acquired at all areas of the display, but can reduce view-angle effects and focus changes that reduce the clarity and contrast of defects located along the curve. This multi-image method could greatly improve defect detection accuracy and repeatability for curved display measurement.

An illustration of a multi-image measurement method that rotates the imaging system to several points across the curve of the display to capture defects in each region at a more “normal” angle.

Want to Learn More about Radiant’s Methods for Measuring Curved Displays?

This week, Radiant comes to Detroit to showcase our solutions for automotive display testing at Vehicle Displays Detroit Symposium & Expo. As part of the Vehicle Displays Technical Program, Radiant’s Automotive Business Leader Matt Scholz will reveal the results of our lab-based study of curved display measurement methods, drawing on the concepts above, and will provide recommendations for measurement approaches and system specifications during a 20-minute presentation.

| Vehicle Displays Detroit, Session 5.5 “Methods for Measuring Small Defects in Curved Displays: Evaluating Approaches and System Specifications” Wednesday, Sept. 25th | 9:35 A.M. - 9:55 A.M. |

Want to join us at the show? Use Radiant’s pass code ndwJXGS to waive the $50 Exhibit Hall fee for Vehicle Displays, and visit Radiant at table #37 to get a live demo of display measurement solutions.

We’re also sticking around on September 26th to offer a half-day seminar on the principles of “Light & Color Measurement,” which presents the science of photometry and how photometric imaging systems are used to objectively evaluate displays and light sources for quality. Register to attend the seminar this week (free to attend, lunch included) at The Henry hotel in Dearborn, Sept. 26 from 10:00 AM to 1:30 PM: https://go.radiantvs.com/light-and-color-seminar-series.html

See you in Detroit!

CITATIONS:

- Lee, H. J., & Kim, S. (2016). Factors Associated with Visual Fatigue from Curved Monitor Use: A Prospective Study of Healthy Subjects. PLOS ONE, 11(10). doi:10.1371/journal.pone.0164022

- Finch, G. (2018, August 16). Monitor Curvature: All the Info You Need About Curved Monitors! [Blog post]. Retrieved from: https://www.viewsonic.com/library/entertainment/monitor-curvature-explained

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List