The Finishing Touch: Ensuring Quality of Touchscreen Display Devices

Back in the days when BlackBerry® phones were all the rage, I bought my first touchscreen laptop. It seemed like magic—just a few quick taps or swipe of the finger to open files, move things around on screen, and navigate the internet. Now most smartphones, eBook readers, and some MP3 players offer touch controls—and many laptops and automotive displays do also. The touchscreen (or "touch screen" or "touch-screen") device market has become a highly competitive space, projected to expand at 8.9% CAGR to reach $121.1 billion in global revenues by 2027.1

Applications for touchscreen technology are widespread, as adoption has grown in parallel with the proliferation of displays in everyday life. Common locations for touch interaction these days include:

- Gas pumps

- Automated teller machines (ATMs)

- Information and retail kiosks

- Tradeshows and conference centers

- Automobile center stack displays

- Car wash centers

- Parking terminals

- Sports arenas

- Supermarket self-checkout

- Building directories

- Restaurants

- Public transport kiosks

- Medical equipment and devices

- Museum exhibits

- And more.

Examples of touchscreen displays used for (clockwise from upper left) smart watches, wayfinding kiosks at Australia’s Royal Liverpool Hospital, and an automobile navigation system. (Kiosk image Source)

The Rise of Touch Screen Technology

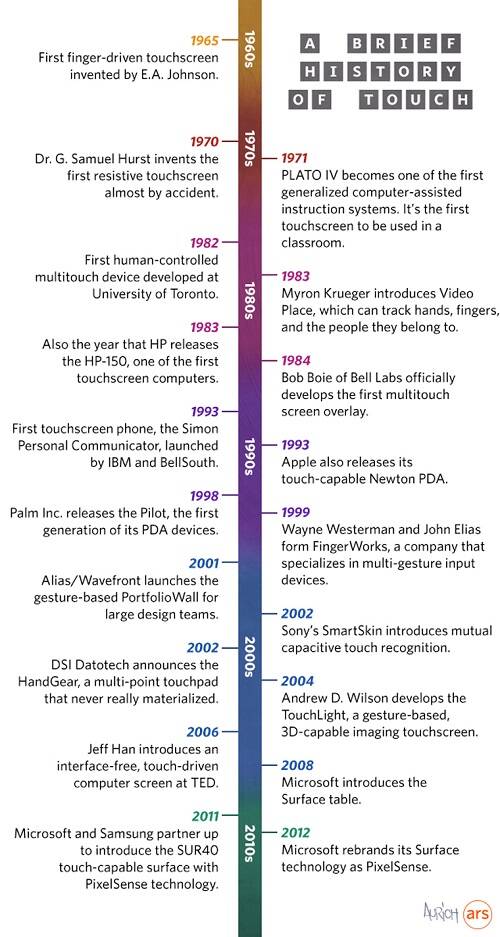

Although touchscreens on consumer devices have only become commonplace in the last decade or so, the first touchscreen was invented way back in 1965. Eric A. Johnson of the Royal Radar Establishment in Malvern, England came up with the original design for a capacitive touchscreen.2

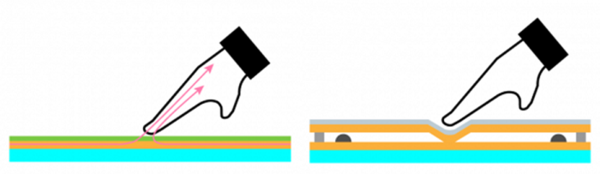

This type of touchscreen uses an insulator layer—such as glass—coated with a transparent conductive film—such as indium tin oxide (ITO). When a user touches the film, the human body acts as an electrical conductor, enabling the device to register the point of contact. Capacitive screens are highly sensitive, responding to even the touch of a fingernail. But they only work with conductive material (e.g., they do not respond to a plastic stylus). They are also limited in being able to register only a single touch point at a time.

Representation of capacitive touchscreen (left) and a resistive touchscreen (right). (Images © Noritake Itran)

In the 1970s, Dr. G. Samuel Hurst and colleagues working at the University of Kentucky developed a new design, the resistive touchscreen.3 This display uses two electrically conductive layers of thin metal film with a tiny air gap in between. When pressure is applied (when a finger or stylus presses down on the screen), the layers are pushed together, completing an electrical circuit. The voltage is read by the device as a location. Resistive touchscreens are less expensive to produce than capacitive and operate using relatively simple algorithms. They have a lack of input precision, however, (especially when used for large-size screens), and can lack overall screen clarity.

A brief history of the touchscreen. (Image © Ars Technica)

In 2007, the original iPhone was released and revolutionized the smartphone industry, featuring a touchscreen instead of a physical keypad. When the iPad came out in 2010, the popularity of touchscreen technology really took off. Microsoft’s Windows® 8 operating system, released in 2012, focused on enabling touchscreen devices, cementing the market position of the technology. Since then, every PC manufacturer has added a touchscreen model to its product line,4 and now virtually every mobile phone and tablet offers the functionality.

Touchscreen Types

In addition to the resistive and capacitive touchscreens described above, other technologies for producing touch-sensitive displays include:

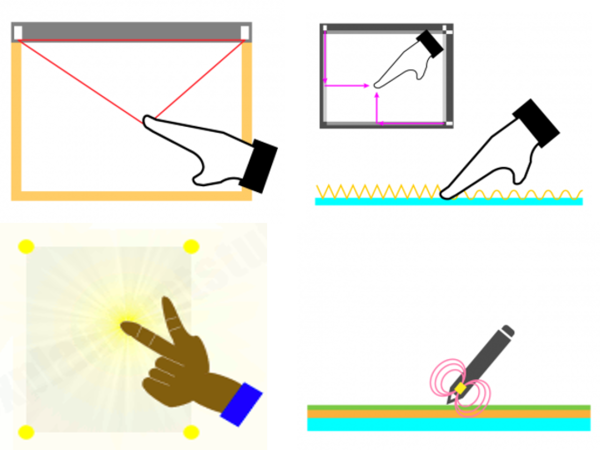

- Infrared (also called Optical Touchscreen). Optical touchscreens use infrared emitters combined with infrared image sensors to continuously scan the touchscreen. When an object comes in contact with screen, it blocks some of the infrared light being received by the sensors. The contact location is then calculated from sensor input and mathematical triangulation. Optical touchscreens offer high transmittance and support multi-touch interaction. Because they use infrared sensors rather than electrical conductivity, they can be operated by any type of material such as a plastic stylus.

- Surface Acoustic Wave. These screens operate by tracking ultrasonic sound waves to identify the location of points on a screen. They’re made with “a single pane of glass, a transmitter, and two piezoelectric receivers. The transmitter produces ultrasonic waves that move over the screen, reflect and then are read by the receiving piezoelectric receivers. When the surface of the glass is touched, some acoustic waves are absorbed, but some bounce back and are detected by the piezoelectric receivers.”5 Acoustic wave touchscreens have high transmittance and long operating lives, thus they are often used where more rugged displays are needed, such as medical facilities, casinos and arcades, and for bank ATMs.

- Near-Field Imaging (NFI). NFI touchscreens operate by sensing the disturbance in an electromagnetic field. As an object such as a person’s finger moves to the screen it effects a change to the electric field on the glass. NFI screen are quite rugged, suitable for military and other extreme operating environments. They can detect touches from any object such as a pen or stylus, and even a hand wearing gloves.

- Electromagnetic Guidance. An electromagnetic guidance touchscreen sends out an electrical charge that reacts with a special stylus. The stylus sends out a signal that allows the touchscreen to precisely identify its position using an electromagnetic induction sensor under a liquid crystal screen. This type of display can respond to high-precision operations, unlike a capacitive touchscreen, although it only works in conjunction with a designated stylus.

Representation (clockwise from upper left) of optical, surface acoustic wave, electromagnetic guidance, and NFI touchscreen technologies. (NFI image Source; other 3 images © Noritake Itran)

Some touchscreens come with additional features that increase their functional capabilities, such as:

- Multi-touch – the screen can detect the presence of more than one point of contact for input. A "10-point" touchscreen will distinguish all ten of a person's fingers separately.

- Pressure sensitivity – the amount of pressure applied to the screen can be detected, adding another layer of input. Devices with this feature include the Apple Watch (“Force Touch”), the iPhone 6S (“3D Touch”), and drawing tablets for digital art.

- Gesture recognition – the touchscreen recognizes certain finger motions as separate commands, such as double-tapping to select text or pinching to zoom out.

- Haptics – recreates the sense of touch to accompany user motion, for example, a vibration is generated when the user is touching the screen.

- Fingerprint resistance – we’ve all spent time cleaning fingerprints and smudges off our device touchscreens. Some newer screens have an oleophobic coating (Greek for "fear of oil") that prevents fingerprint oils from sticking to the surface.

The latest innovations in touchscreen technology include:

- Ultra-thin touchscreen film. Researchers at RMIT University in Australia have used liquid metal chemistry to shrink 3D touchscreen film down to virtually 2 dimensions. The nano-thin, ultra-flexible electronic material could be printed and rolled out like newspaper for the touchscreens of the future. Learn more…

- Spray-on touchscreen. Scientists at Carnegie Mellon University have developed a spray—called Electrick—that’s composed of an electrically conductive carbon-based material. Sprayed onto an object, it enables the object to conduct electricity, which can then be measured to track the movement of a user’s finger. The spray can be applied to multiple surfaces – from plastic and furniture to…jelly.6Learn more…

- Wearable Touchscreen. As if touchscreen jelly wasn’t enough, Levi Strauss & Co has partnered with Google to develop ‘smart denim’. The first concept garment produced will be a jacket with conductive fibers woven into the left cuff, making it touch sensitive. The touch inputs are sent to the user’s phone via a Bluetooth cufflink. The jacket is slated to go on sale for $350 in Autumn 2020.7

Touchscreen Display Quality Control

Like any consumer display product, touchscreen devices require rigorous quality inspection to ensure that their functionality, performance, and appearance meet brand standards and customer expectations. Since the early days of mass-market touchscreen devices, Radiant has helped manufacturers to detect cosmetic defects on surfaces and displays to ensure quality in design and production. Using a ProMetric® Imaging Photometer or Colorimeter with TrueTest™ Software provides an automated inspection solution that matches the perception and acuity of human vision, providing manufacturers and consumer alike with exactly the level of high-quality device they expect.

Radiant’s ProMetric® I-Series Imaging Colorimeter (left) and ProMetric Y-Series Imaging Photometer (right).

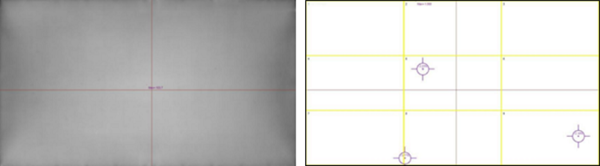

Radiant’s Advanced Vision solutions enable precise detection of particles and foreign materials on or within transparent substrates like clear plastic, film, or glass—all of which may make up the multiple layers of touchscreen displays. Our automated visual inspection systems are specially calibrated to detect and distinguish particles and their locations. Understanding whether a particle is on the top or bottom of a surface, or embedded within or between layers, allows manufacturers to adjust operational processes to determine if an inspected material can move on to the next phase of production, if cleaning is required, or if the material must be rejected as scrap.

Leveraging high-resolution image sensors, our ProMetric imaging systems achieve unmatched image clarity to detect the smallest, pixel-sized particles and defects—at production-line speed. Radiant’s visual inspection solutions can even detect defects that may go unnoticed by human inspectors, including tiny, light-colored debris on glass or metal surfaces.

Radiant’s TrueTest™ automated visual inspection software detects particles on a device surface that appear invisible to the human eye.

CITATIONS

- “Touch Screen Display Market….Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2019-2029”, Transparency Market Research, April 3, 2020.

- “Touchscreens: Past, Present, and Future”, Displays2Go, January 9, 2018; last modified January 19, 2018.

- Ibid.

- “Touchscreen Technology on the Rise”, Brave River Solutions. (Retrieved September 10, 2020).

- “What are the different types of touchscreens and how are they used?”, Noritake itran. (Retrieved September 10, 2020).

- “The Latest Touchscreen Technology: 4 Amazing Innovations”, Acante. (Retrieved September 10, 2020).

- Ibid.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List