Keeping Things in Focus: XR Display Measurement Solution with Electronic Lens & Auto-Focus Capability

Makers of AR/VR/MR (augmented, virtual, and mixed reality) devices, collectively referred to as extended reality (XR), face multiple design challenges. The human eye and visual processing system is quite complex and highly sensitive to minute differences in light, color, motion, shape, and perspective. XR device designers need to provide realistic and appealing visual experiences to users, free of image defects or distortions. At the same time, they must be careful to avoid subtle performance issues such as latency that can cause headset wearers to feel sick or suffer other ill effects.

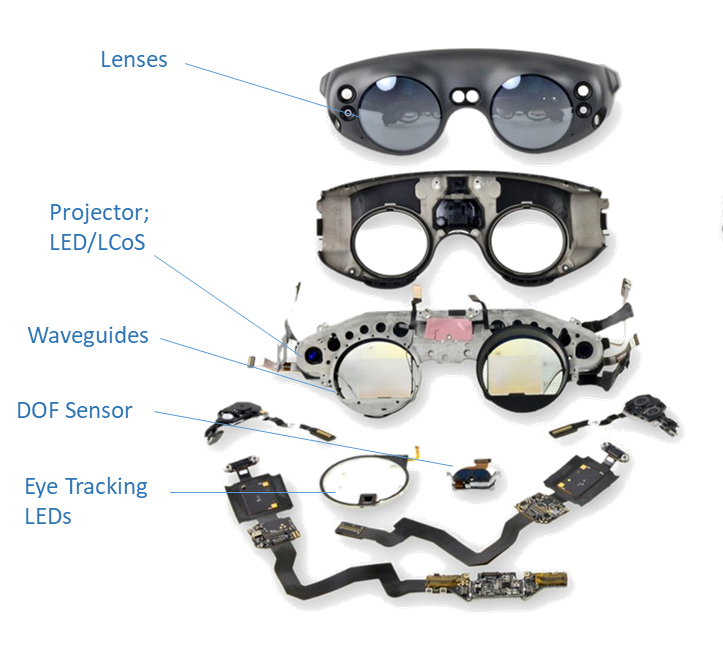

XR device companies must continually develop and fine tune virtually every aspect of their products, including hardware and optical elements such as lenses and waveguides, light and displays, sensors, form factor, headset weight, and wearer comfort. They also have to grapple with processing systems, software, and image quality.

An essential part of the device development process is being able to try out and test different design elements and iterations. For this, device makers need a range of quality testing systems. For example, to measure visual display performance, an XR display metrology solution is required.

A look at some of the many optical components of an XR device, in this case the Magic Leap One MR headset. (Image source: IFIXIT)

Requirements of XR Display Measurement

Looking solely at the visual elements of an XR optical system, the standards for device quality and performance are defined by human visual perception—how the XR display appears to the user. We can define the “XR display” as the composite visual elements produced and transmitted by integrated displays, projection units, and associated optical modules within the device. The task for developers is to measure the performance of these elements accurately and efficiently to support multiple design iterations as they work to perfect their devices.

Fundamentally, the quality of an XR display is dependent on a user’s perception of the light relayed to the retina from the display and optical elements in the device. Thus, evaluating light and images as perceived by a user is key.

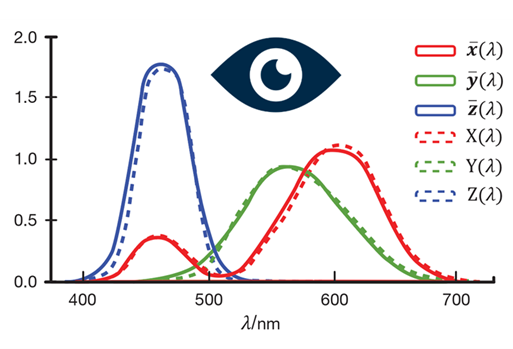

Because these displays are viewed near to the eye, within a headset, and across a specific angular field of view (FOV), XR display testing solutions need to replicate the viewing conditions of the user as much as possible. To measure the properties of light and illuminated displays, photometry-based systems, such as Radiant’s ProMetric® Imaging Photometers and Colorimeters, are specifically designed to match the human eye’s perception of light (luminance) and color (chromaticity).

A metrology system’s response must conform to standard functions describing the human visual response to light. Radiant ProMetric® Imaging Photometers and Colorimeters have optical filters that precisely match CIE color-matching functions, which plot standard human visual response to light and color. Response match ensures accurate luminance and chromaticity measurements.

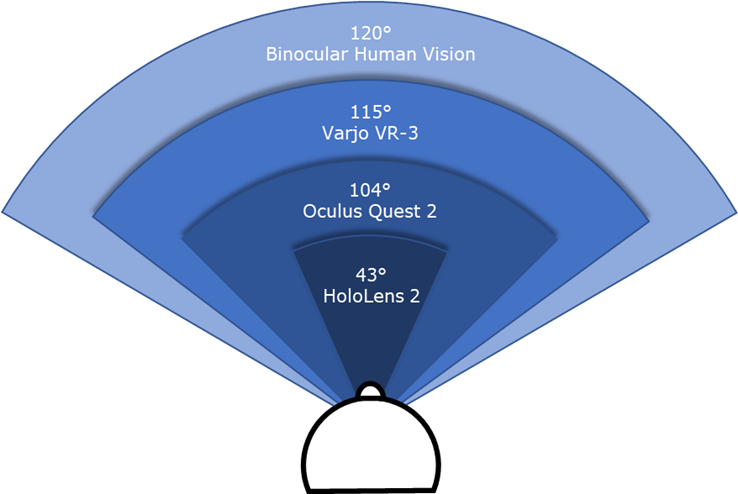

But replicating an XR device user’s complete viewing conditions requires more than just taking accurate measurements. A solution also needs to characterize display properties derived from context by comparing values across an image. These values can include uniformity (which could be luminance, chromaticity, or focus uniformity), as well as overall contrast, distortion, modulation transfer function (or MTF), the occurrence and location of defects, and other qualities. Measuring and evaluating XR displays can be further complicated by the range of FOVs of different devices, by different display resolutions (pixels per degree, PPD), and variations of the focus distance.

A few examples of the wide range of FOVs (measured in horizontal degrees) among different XR devices.

The Challenge of Focus

One characteristic of human vision is the way our eyes focus to perceive details. We can clearly make out objects and the environment that are right in front of our nose or many miles away, because our eyes can adjust their focus distance almost instantly. A region in the center of the retina, called the fovea, contains a dense concentration of a type of photoreceptor cells called cones. The cones enable us to see highly precise and detailed images in the central area of our visual field.

Areas around the fovea contain progressively fewer cones the farther they are from the center, thus our visual perception becomes less precise towards the outer portions of our FOV. On the far edges of peripheral vision, we have little perceptivity beyond just distinguishing light and dark or detecting movement (a survival advantage for ancient humans to spot predators).

To create a realistic viewing experience, XR device makers want images to have sufficient detail. But if every area of an image were displayed in full detail all the time—on today’s high-resolution displays—it would require a tremendous amount of processing power—more than a user could comfortably carry around on their head!

To reduce computational demands on XR devices, some headsets now rely on “foveated rendering.” This approach continually adjusts the amount of detail displayed in different parts of an image, with the sharpest detail in the foveal region. The more peripheral areas of the image are less detailed or blurry, just as they would appear in our natural vision.

Example of foveated rendering from Tobii that uses gaze-tracking hardware to adjust image appearance (and processing load) based on where the user directs their eyes. (Image Source)

To accommodate this aspect of human vision, it’s becoming more common that XR headsets are designed with multiple focal distances for more natural viewing scenarios. For example, 1 focal point for perceiving elements as “near” and a 2nd focal point for elements far away. Multi-focal, varifocal, and foveated optics, and new dynamic focusing optics such as liquid lenses, create a need to measure more than 1 focal distance or region.

Many AR/VR display measurement solutions on the market allow the focus distance to be changed, but only by manually refocusing the camera lens. This can cause challenges for measurement because manual refocusing is often imprecise or inconsistent, not to mention time-consuming.

The Effect of Focus on Measurement Accuracy

Poor focus introduced by the measurement system can impact measurement accuracy, introducing apparent variations not inherent in the XR display. For example, a display device could fail an MTF test because it has low image clarity introduced by the poor focus of the measurement system.

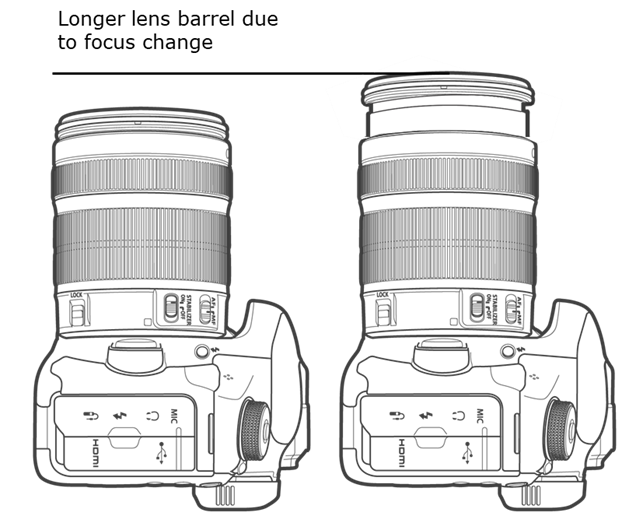

Another factor that makes measuring variable focal points challenging is that the lens barrel of a traditional lens changes its length as focus changes. This moves the position of the imaging system’s entrance pupil relative to the display, which throws off measurement accuracy.

To address this, the imaging system needs to be repositioned whenever the focus is adjusted so that the entrance pupil is restored to the correct measurement location. This not only takes time but increases the risk that there could be an error in measurement setup. Manually adjusting the measurement set up for every slight change in focus is inefficient, inconvenient, and completely impractical for mass-production testing.

The barrel of a tradition lens changes length when focus is adjusted, moving the aperture outside of the target entrance pupil position, and requiring the entire system to be repositioned with each focus change.

Measuring at different focal distances requires changing the measurement set up each time, or even using different measurement systems. What device makers need is a single XR display measurement solution to accommodate multiple focal points, quickly and easily.

The XRE Lens: A Flexible Solution

Radiant’s XRE Lens addresses these testing needs with a new, patent-pending design that incorporates a unique internal-focus mechanism. The system provides electronic focusing that can instantly adjust to multiple focal planes. Used with a ProMetric camera and the TT-ARVR™ module of our TrueTest™ software, the XRE Lens can be set to precise focal distances (from 0.5 m to infinity).

Since the XRE Lens’s focus mechanism is internal, refocusing does not increase the overall length of the system or change the position of the entrance pupil prior to capturing a new measurement. It eliminates the need for manual refocusing and reduces potential alignment and focus errors. And, the lens system can function hands-free during focus adjustment, meaning electronic focus can be automated in sync with measurement sequences for maximum efficiency.

Radiant’s XRE Lens solution, in folded configuration paired with a ProMetric I Imaging Colorimeter (back) and non-folded with a ProMetric Y Imaging Photometer (front).

The XRE Lens has been designed to provide XR device makers with the flexibility to meet the unique measurement parameters of their device, reducing the need for costly and time-consuming custom solutions. Its flexible options and features include:

- Folded or non-folded optical configurations of the XRE Lens that enable in-headset and dual-eye measurement.

- Choice of integrated imaging colorimeter for color measurement, or imaging photometer for brightness measurement only.

- Several image resolution options, with a choice of 29, 45, and 61MP to ensure optimal PPD.

- Fully automated Through-Focus MTF testing

- Entrance pupil (aperture) in front of lens to simulate the human eye position

- Virtual aperture (3.3 mm) for flexible positioning at various eye relief distances

- System FOV up to ±35° (70° total)

- Integration capability to production systems

In total, there are 24 possible solution configurations to meet any number of requirements. And, every XRE solution comes with electronic focus capability, a full angle FOV up to 70˚, and works with TT-ARVR software for rapid, automated testing whether in R&D or production stages.

To learn more about the visualization parameters and quality considerations of XR devices, measuring headsets to emulate the human eye, and how the XRE Lens is engineered specifically to meet those requirements, watch the webinar “Replicating Human Vision for XR Display Testing: A Flexible Optical Solution for In-Headset Measurement” presented by Radiant’s Optical Development Manager.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List