When Automated Inspection Meets Human Vision

Machine vision has been a boon to manufacturers, enabling visual inspection at production-line speeds with consistency, repeatability, and objective data. Yet there are still some visual inspection tasks that are beyond the capability of typical machine vision systems. Complex assemblies, subtle surface defects, areas of low-contrast, and glass or transparent materials require a higher level of visual acuity, which has often been provided by human inspectors. Human inspectors, however, can be costly and are subject to inconsistency and fatigue.

Human inspector performs visual quality checks on the production line.

Radiant’s Advanced Vision solutions are a new class of automated visual inspection technology. Our approach combines the benefits of automated machine vision inspection systems with the power of true human vision. Based on photometric imaging principles for light measurement, our sophisticated imaging technologies and software offer capabilities that go beyond traditional machine vision systems when used to inspect devices and non-lit surfaces, in addition to illuminated displays.

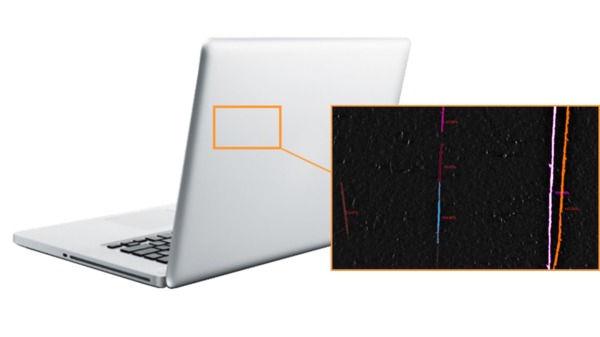

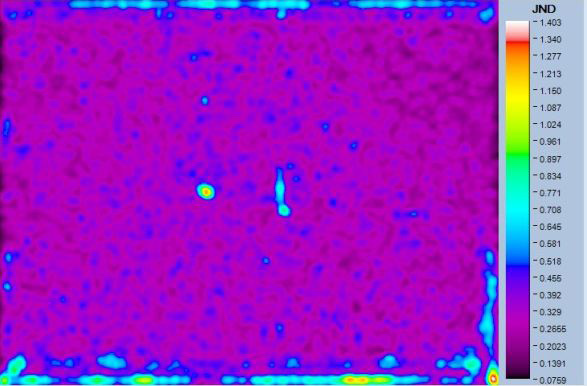

Scratches on the back of a laptop are identified and qualified based on their “just noticeable difference” (JND) values (severity as compared with the rest of the surface). The values shown in this analysis image provide contrast ratios relative to a background level.

Advanced Vision is the application of high-resolution, high-dynamic-range, and low-noise imaging that matches—or even exceeds—the capability of human vision to detect flaws. Although a wide variety of defects are easily detectable to the human eye, the accuracy of human inspection decreases precipitously as the complexity of a surface or assembly increases. Automated visual inspection solutions from Radiant capture extremely detailed images of complex parts thanks to the high resolution and high dynamic range of our imaging photometers.

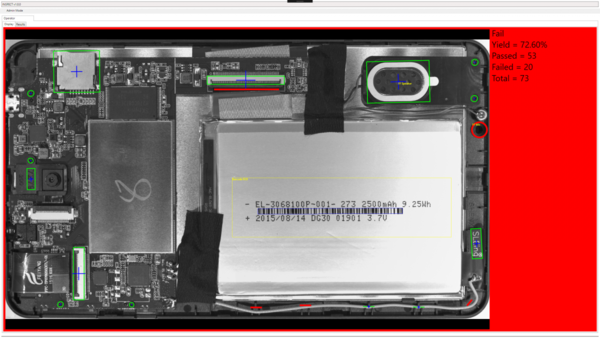

Radiant's INSPECT.assembly™ verifies component presence, placement, and alignment in complex assemblies with greater accuracy and repeatability than human inspectors. This device fails inspection due to a misaligned connector (top of image), missing screw (right side), and misrouted cable (accross the bottom of the image).

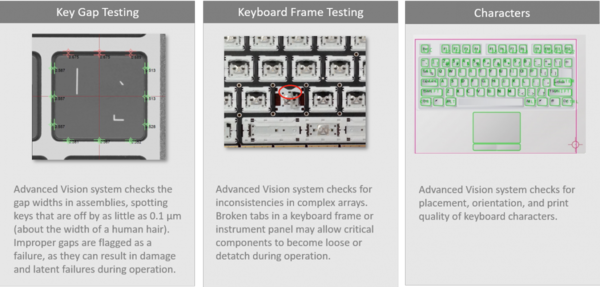

Photometry-based imaging can detect variations in brightness and color from key to key on illuminated keyboards, and even within keys, that are noticeable to the end user. Advanced Vision imaging systems are also effective for a variety of keyboard assembly inspection tasks including testing for key gap widths, keyboard frames, and characters.

Ideal for cosmetic surface inspection, high-precision assembly (e.g., verifying component presence and placement), glass inspection, and particle detection, Advanced Vision solutions can help you achieve absolute product quality while improving throughput, increasing inspection accuracy & repeatability, reducing escapes, and ensuring customer satisfaction.

Functional testing may not catch subtle defects such as loose connectors or missing screws, which can cause latent failure once the product is shipped and in customer hands.

See Advanced Vision Inspection in Action

If you’re in the Chicago area next week, come check out the Automate conference and expo (April 8-11), which “brings together North America's broadest range of automation solutions, [including] the latest in robotics, machine vision, AI, motion control, and related technologies.” Radiant will be there (Booth #9237) with live demos of several of our automated visual inspection technologies, including display test and Advanced Vision for quality control in electronics production.

Radiant’s visual inspection solutions pair the specialized optics and imaging technology of our ProMetric® Imaging Photometers and Colorimeters with advanced algorithms to locate and characterize cosmetic defects. Our imaging systems feature scientific-grade image sensors with extremely high resolution, dynamic range, and signal-to-noise ratio for precise and repeatable image-based measurements. Image noise is carefully reduced by testing each sensor's specifications within the overall system design (combined with optics, electronics, hardware, etc.), enabling our imaging systems to detect more surface variations and defects than most high-resolution measurement cameras.

Analysis of an illuminated display (with luminance illustrated in false color) shows blemishes (mura) detected by the TrueMURA™ module of Radiant’s TrueTest™ software suite.

At Automate, we’ll demonstrate how our photometry-based systems are applied in visual inspection applications of internal components (cables, connectors, screws), displays (luminance uniformity) and surfaces (scratches, dents, debris) to achieve accuracy beyond the capability of human inspectors. Radiant turnkey systems are engineered to address specific production needs. These systems function continuously without downtime, outperforming multiple human inspectors doing repeat inspections.

Can’t make it to Automate? Or, just want to learn more about the technology and applications of Radiant's Advanced Vision automated inspection solutions? Read our new eBook for an in-depth exploration of the features and benefits of this innovative new approach.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List