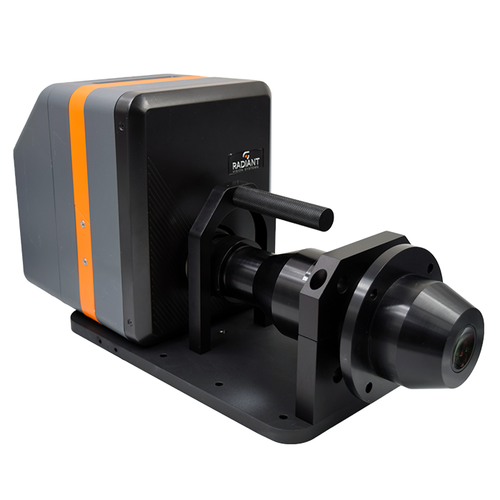

FPD Conoscope Lens

Provides fast, accurate, cost-effective view-angle performance measurement for flat panel displays.

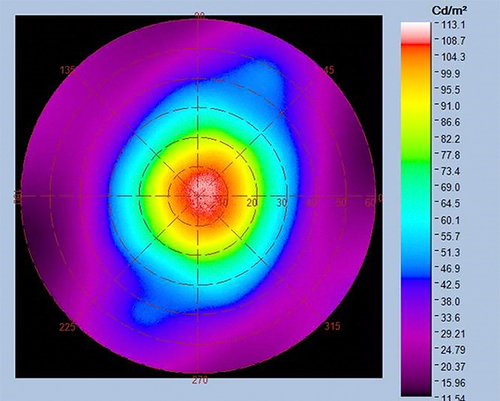

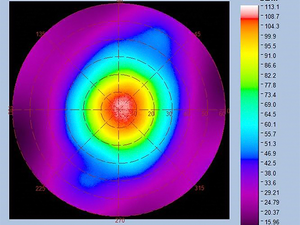

The Radiant Vision Systems FPD (flat panel display) Conoscope Lens enables high-resolution photopic measurement of the angular distribution of color, luminance, and contrast for displays and display components. Radiant uses Fourier optics that map an emitting spot to an image sensor so that each pixel corresponds to a different emission angle.

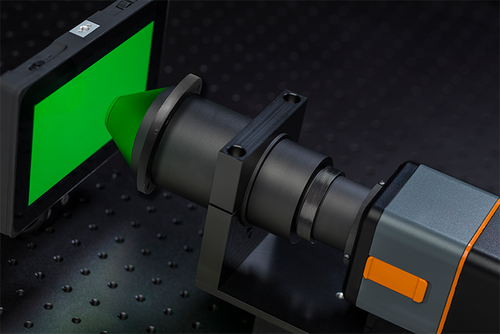

The FPD Conoscope Lens captures a full cone of view angle data in a single measurement to ±70 degrees. This provides quick, accurate results, making the system ideal for both R&D projects and in-line production quality control. The lens is well-suited to a wide range of FPD types including those based on LCD, OLED, and backlight technologies.

High-Resolution Angular Measurement

The FPD Conoscope Lens provides an angular resolution of 0.05 degrees per sensor pixel. Paired with a ProMetric® I Colorimeter or Y Photometer, the Conoscope Lens has the capability to measure luminance, radiance, angular contrast, CIE chromaticity coordinates, and correlated color temperature (CCT) with a high degree of accuracy at each view angle.

Seamless Evaluation from R&D to Production Lines

The FPD Conoscope Lens simultaneously acquires view angle measurements to ±70 degrees. Designed to mount directly to a ProMetric camera, the lens and camera combination can be purchased for a fraction of the cost of alternative solutions, and offer reduced hardware size and complexity compared to typical goniometric measurement systems for R&D applications.

Because of its speed and compact form factor, the FPD Conoscope Lens solution is also ideally suited for in-line inspection of flat panel displays during production. It provides real-time pass/reject operations based on display view angle performance data, eliminating poor-quality components from the line and identifying quality trends before significant materials loss. With the FPD Conoscope Lens accessory, Radiant Vision Systems cameras can be used in both R&D and production environments to capture identical measurements of view angle data for seamless evaluation of displays throughout an entire product lifecycle, from initial characterization to quality control.

Mount to ProMetric Photometers and Colorimeters

The FPD Conoscope Lens mounts directly to a ProMetric Y Imaging Photometer or ProMetric I Imaging Colorimeter using a custom bracket. Mounting the lens directly to a ProMetric imaging photometer or colorimeter offers the most efficient means of measuring view angle performance using a turnkey, compact camera solution that requires minimal setup and integration time, equipment, or expertise.

As part of the ProMetric family of imaging colorimeters and photometers, the FPD Conoscope Lens and ProMetric camera solution also comes with ProMetric Software, a powerful software suite that provides equipment control, data acquisition and image analysis. The software facilitates intuitive camera set-up and customizable measurement parameters, and supports extensive data analysis and display functions, including isometric plots, cross-section graphs, radar plots, bitmaps, and CIE color plots.

FPD Conoscope Lens Key Features and Highlights:

- Accurate, reliable measurement of luminance, chromaticity, and contrast to ±70° view angle

- Faster than goniometric systems, capturing data for all angles simultaneously

- Easily paired with ProMetric imaging colorimeters or photometers

- Combination of low cost, high performance, and flexibility, designed for R&D and quality assurance labs

- Easy-to-use measurement control and analysis software

| Parameter | FPD Conoscope Lens | |||

|---|---|---|---|---|

| Application | View angle measurement | |||

| Working Distance | 3 mm | |||

| Minimum Sampling Area (uniform emission) | 15 mm diameter | |||

| View Angle | ± 70° | |||

| Resolution | 0.05° / sensor pixel (29MP) | 0.03° / sensor pixel (45MP) | 0.03° / sensor pixel (61MP) | |

| Luminance - Minimum | 0.01 cd/m2 | |||

| Luminance - Maximum | 3,000 cd/m2 (Y-series); 30,000 cd/m2 (I-series*) | |||

| System Accuracy** | 0-60° Inclination Luminance (Y) ± 4% Color Coordinates (x,y) ± 0.004 |

60-70° Inclination Luminance (Y) ± 5% Color Coordinates (x,y) ± 0.007 |

||

| Measurement Capabilities*** | Luminance, Radiance, Angular Contrast, CIE Chromaticity Coordinates, Correlated Color Temperature (CCT) |

|||

| Units*** | cd/m2, nit, W/sr/m2, foot-lambert, CIE (x, y) and (u’, v’), Kelvin (CCT) | |||

* Based on ND1 configuration for I-series. For higher luminance sources, contact [email protected].

** Accuracy dependent on spectrum under test and color calibration methods applied

*** Color measurement available with I-series cameras only

Specifications subject to change without notice. If there are any discrepancies between these specifications and the specifications shown in the PDF Product Spec Sheet, the product Spec Sheet is considered correct.

Compatible Products:

- ProMetric Y Series Photometers: Y45, Y61

- ProMetric I Series Colorimeters: I29, I45, I61. I61-SC

System Recommendations:

- ProMetric Imaging Photometer or Colorimeter (29MP or higher)

- TrueTest™ Software

- Windows® 10, 64 bit

- 16-32 GB RAM

- Additional system requirements vary by camera.

Typical Applications

The FPD Conoscope Lens simplifies the process of capturing view angle measurements using a single compact camera solution, and addresses both off-line and in-line applications:

- View angle performance measurement for LCD, OLED, and other flat panel displays

- Technology evaluation and characterization in display R&D and quality control settings

- In-line quality control during display manufacturing