A Taxonomy of Displays: Transmissive, Reflective, Emissive & More

Displays are proliferating in the world as we are increasingly surrounded by smartphones, digital signage, computers, e-readers, touchscreen appliances, smart watches, televisions, tablets, interactive kiosks, and more. This display landscape encompasses myriad technologies, materials, and complex engineering, from the liquid crystals in LCD screens to the organic layer of OLED displays to nanoscale quantum dots. Today we take a look at the taxonomy of displays, how each display type works, and the differences between them.

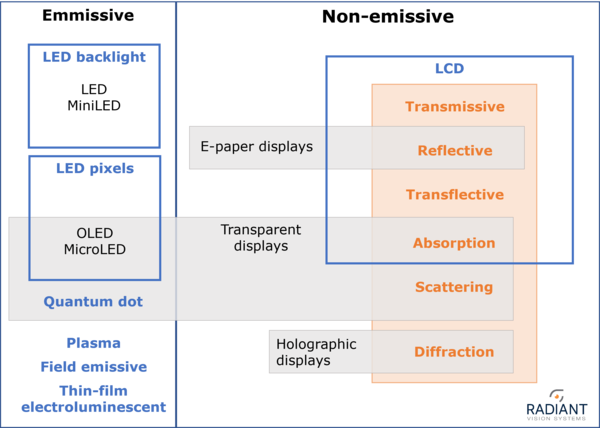

Emissive Vs. Non-emissive

The common thread among all electronic displays is illumination—there must be some light source to create the digital images that a user sees on the device screen. A key distinction in display types is between those that are based on emissive technologies (they produce their own light) versus those that are non-emissive (they rely on a separate light source).

For emissive displays, each pixel in the display screen is an emitter—an element that outputs light when electric current is applied. For example, an OLED display contains millions of tiny diodes that give off red, green, blue, or white light, which combines to form the images on the screen. Emissive displays include multiple types, where each LED (light emitting diode) is a pixel:

- LED displays such as large-format outdoor signage and video screens

- OLED displays (organic LED, including active matrix, AMOLED, and passive matrix, PMOLED) have become a common technology for today’s computer and smartphone display screens due to their brightness, vivid colors, and energy efficiency

- MicroLED displays are emerging into the market, currently found primarily in high-end, ultra-high-resolution televisions but gaining ground due to visual performance that exceeds OLED

LEDs, and their smaller cousins miniLEDs, are also used in non-emissive displays such as LCDs as the backlights that illuminate the display pixels from behind.

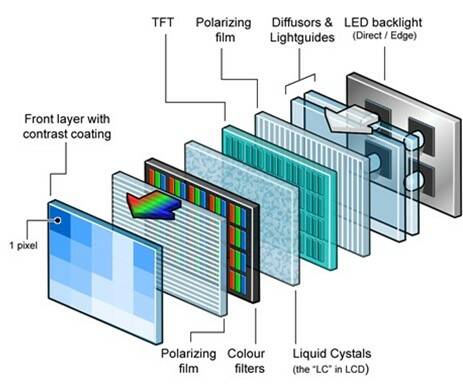

LCD Display Layers

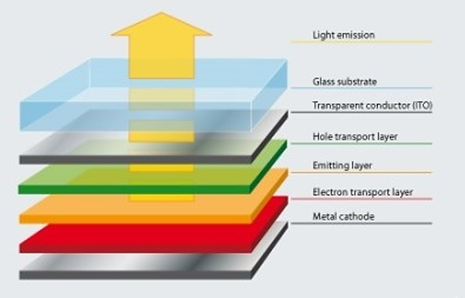

OLED Display Layers

The structure of a typical non-emissive LCD (top) where LEDs are used for backlight illumination of subsequent layers, and an emissive OLED (bottom) where the “emitting layer” of organic LEDs creates light for the high-resolution images that are viewed on-screen. (Top image: FlatpanelsHD, bottom image: Android Authority)

The popularity of emissive displays such as OLED is due to the quality of the visual experience they provide: “The majority of emissive displays are Lambertian emitters, meaning luminances from different viewing angles are the same, resulting in wide viewing angle performance. Due to self-emissive characteristics, these displays can be used in low ambient light conditions. Emissive displays tend to have very high contrast ratios, since they are completely dark when turned off.”1

Plasma Display Panels (PDP) are another emissive display type that use tiny colored fluorescent pixels (red, green, and blue) to form the illuminated images on screen. The fluorescent light comes from plasma, a gas that is excited by electric charge. Field Emissive Displays (FED) and Vacuum Fluorescence Displays (VFD, now obsolete) also fall into the emissive display category.

Quantum Dot (QD) displays are called photo-emissive. A blue (or UV) backlight irradiates a QD semiconductor nanocrystal layer causing the dots to emit pure basic colors. Still in the experimental phase are electro-emissive (or electroluminescent) QD displays that use QD light emitting diodes (QDLED or QD-LED).

LCDs and Non-Emissive Displays

Among non-emissive displays, most are liquid crystal displays (LCD). A layer of liquid crystal molecules is sandwiched between two thin layers of polarized glass with a light source such as a backlight panel or reflector that illuminates the pixels. LCD displays can operate via three different illumination configurations, making them suitable for use a wide range of ambient light conditions:

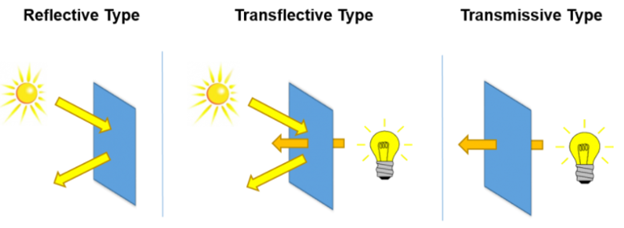

- Transmissive – light from a backlight source passes through the LCD. “The LCD glass or panel functions as an ‘optical switch’ where light from the backlight passes through the LCD cell depending on the orientation of liquid crystal molecules. The orientation can be ‘switched’ on or off by an electrical field.”2 Backlights can produce a lot of light, making the display image bright. However, traditional backlights also use a large amount of energy because they are always “on” even if there is no image content being displayed (for instance, a television that is turned on but displaying a black screen).

- Reflective – ambient light provides illumination. Typically, a mirror is located behind the liquid crystal layer that receives and then reflects light back through the LCD. These displays have the advantage of low energy use and being highly readable in outdoor settings even in bright sunlight. LCD displays can be reflective, for example liquid crystal on silicon (LCoS) panels. But the most common application of reflective lighting today is electronic paper (e-paper) displays. The images on an e-paper display are created by manipulating electrically charged black and white particles (or more recently, colored particles), but the illumination source is reflected ambient light.

- Transflective – uses a combination of both reflective and transmissive light sources. For example, an LCD with a semi-transparent reflective layer that allows the backlight to shine through when needed, and a reflective layer with a hole for each pixel to reflect ambient light when appropriate. This enables the display to switch from reflective mode to transmissive depending on ambient light conditions to optimize image visibility, for example from daytime to nighttime.

Comparing the light source mechanism of reflective, transflective, and transmissive displays. (Image: New Vision Display)

Other non-emissive displays operate using a range of lighting mechanisms, including:

- Absorption – Some transparent displays use an absorptive approach. Liquid crystals are transparent, so light in varying intensityies can be projected on a clear LCD panel to create images. Some transparent augmented reality (AR) and head-up display (HUD) screens operate this way.

- Scattering – Some transparent displays are made with nanoparticles that scatter light selectively to create images. Applications for this type of display can include retail windows and HUDs. For example, the application of special light-scattering clear film can turn any glass surface into a display.

A light-scattering display from Lux Labs that uses a window to show a series of images.

- Diffraction – Unlike other displays, diffractive displays do not require a panel or surface to show image content. Holographic images can be projected (by lasers, for example) into the air, exciting the molecules so that light is diffracted into 3D shapes that can be viewed from any angle.

A visual taxonomy of display screens; the different lighting mechanisms are in orange. LCDs are most often transmissive, reflective, or transflective. E-paper displays also use reflective illumination. Transparent displays can employ absorptive techniques, scattering techniques using LCD panels with an absorptive light mechanism, or they can use emissive display elements. Holographic displays typically rely on light diffraction to create 3D images.

Reflective Display Technology for Vision Health

Display technologies such as OLED are popular for many applications in part due to their brightness and contrast (for visibility in a range of ambient light conditions) and their vivid color rendering. However, some medical experts are concerned about the effect of bright light—especially blue light—on human health. Issues such as eye strain and interruption of circadian sleep patterns have been attributed in part to display screens.

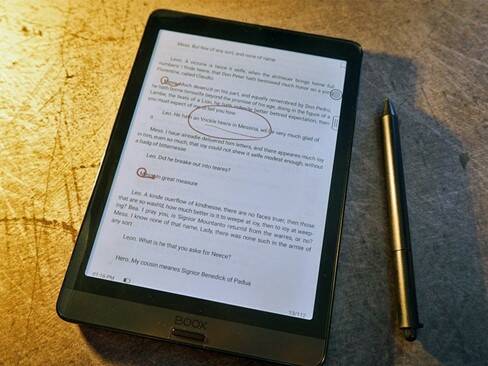

One reason that e-paper displays have caught on in the electronic reader product space (e.g., Kindle, Nook) is that reflective technology is less tiring for our eyes.3 Human vision evolved to perceive the light (e.g., from the sun) reflected off surfaces as objects our world. For example, a red apple appears red to us because all other wavelengths of light (green, yellow, indigo, etc.) are absorbed while only the red spectrum of wavelengths are reflected off the apple into our eyes. E-paper displays reflect light to our eyes just like the printed paper of a book and are therefore much more natural for our eyes to perceive.

The new Onyx BOOX Note Air e-reader device with e-paper display and touchscreen note-taking capabilities. (Image: © Onyx)

New reflective LCD (RLCD) displays are also in development. They take advantage of versatile and cost-effective LCD technology with its well-established fabrication supply chain but use reflection (for example from front-lighting technology) to mitigate the amount of bright light shining directly in our eyes.

Ensuring Display Brightness, Color, and Visual Performance

Human ingenuity has brought us a broad range of display technologies and illumination approaches. Each has its strengths and weaknesses and are more or less suitable for a variety of display applications. What all electronic displays have in common is a prerequisite for visual performance: all displays must present digital content to a viewer in the most clear and legible form, while balancing considerations such as energy efficiency and fabrication costs.

Display manufacturers rely on visual inspection during development and production to ensure that display quality and performance meet brand standards and customer expectations. For the utmost efficiency and precision, automated visual inspection systems that employ photometric imaging provide calibrated luminance, chromaticity, and defect data for any type of display at speed.

Whatever technology underlies a display device, Radiant has the expertise and a solution to measure it. For thirty years we’ve provided industry-leading hardware and software solutions for automated visual inspection of displays: from flat panel monitors to curved automotive displays; from virtual reality headsets to transparent HUDs; from LCD televisions to emissive displays down to the pixel and subpixel level.

Our versatile ProMetric® Imaging Photometers and Colorimeters come in a range of high-resolution sensor options that optimize accuracy and speed for automated display inspection in labs and on production lines. Combined with our TrueTest™ Software, our ProMetric solution enables display makers to identify defects, measure and correct uniformity, and evaluate multiple visual performance parameters quickly and easily to ensure the end product provides the desired user experience.

Radiant’s display inspection solutions include (left to right) ProMetric® I Imaging Colorimeter, ProMetric Y Imaging Photometer, TrueTest Software (with multiple modules for special unique applications such as AR/VR devices and automotive displays), and ProMetric I with our FPD Conoscope Lens to evaluate display view angle performance.

CITATIONS

- Roehrig, H., “Displays Chapter 2: Physical Characterization & Image Quality.” Displays for Medical Imaging, published by the Society for Imaging Informatics in Medicine, Krupinsky, E. Editor. (Retrieved July 15, 2021)

- “What LCD Modes Mean: Reflective, Transmisssive, Transflective.” New Vision Display, March 14, 2017.

- Casper, M., “Developments in New IT Products Using Reflective LCDs.” Presented at Society for Information Display (SID) Display Week 2020 Business Conference.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List