Quality Considerations for Marine Displays

When out at sea, a ship’s captain needs instant access to clear and accurate information to navigate and maintain vessel operations and safety. In the early days of cross-oceanic sailing, instruments like a compass, telescope, sextant, and hourglass were among the few tools that mariners had to help them on the journey. Today, a panoply of electronic instruments, sensing systems, and display screens offer seafarers extensive real-time information and advanced communications capabilities.

A sextant made by the Kelvin Hughes company of London in 1917; the company still makes navigation systems today, of the modern, electronic type.

Today’s vessels might contain some or all of the following electronic systems: radar (S-band and X-band), autopilot navigation system, ARPA (Automatic Radar Plotting Aid), a speed and distance tracking log, echo sounder, an electronic chart display information system (ECDIS) with detailed maps and charts of oceans and waterways, a GPS system, an automatic identification system (AIS) transponder that uses UHF radio for ship-to-ship communication, a rate of turn indicator, and a rudder angle indicator. Some ships also have a long-range identification and tracking system (LRIT) and a voyage data recorder (VDR), similar to the “black box” on an airplane that records the vessel’s data and status information throughout a journey.

The Unique Demands of Marine Displays

Many of these systems use electronic display screens to display and update information for a ship’s crew—but not just any screens. Displays intended for use in marine vessels must be able to withstand harsh conditions and be readable in all types of weather, day or night. Marine displays are a sub-segment of the Industrial Display (ID) market that is referred to as Rugged Displays. The rugged ID category includes displays with similar high reliability and durability requirements, such as those used in manufacturing environments, industrial equipment, automobiles, aerospace, military, power stations, and outdoor digital signage.

On board a vessel, displays may be regularly subjected to conditions such as:

- Direct sunlight

- Extreme temperatures

- Moisture from both fresh and salt water, including potential temporary immersion

- Dust and other contaminants

- Movement and vibration

- Impact

To make screens more functional for marine use, manufacturers may use elements such as anti-reflective films to improve visibility in daylight, called “sunlight readable” displays in industry parlance. Shatter-proof glass and heavy-duty bezels and casings can be used to improve durability. Displays are typically installed in a boat’s cockpit or pilot house, or on the bridge of a ship, but can also be found inside the cabin for passenger entertainment, or throughout a larger vessel for informational display signage (such as on cruise ships).

Marine displays accounted for smallest segment of the ID market in 2016; however, this segment is expected to grow at an estimated CAGR of more than 6% through 2025.1 This growth “is attributed to [their] wide range of applications including real-time sonar system for ships, Ethernet integrated combat system for battleships & tank balancing system, unmanned monitoring systems for seaport power substations, and the ship engine monitoring system.”2

A view of multiple display screens, instruments, and systems on the bridge of the Research Vessel Sikuliaq, docked in Ketchikan, Alaska. (Photo credit: NorthbySouthBaranof, license CC BY-SA 4.0)

Marine Display Technologies & Applications

Adoption of new display technologies in the marine industry has followed a pathway similar to the consumer display industry. Marine display types now encompass LCD, LED, OLED and ePaper technologies. LCD currently accounts for more than 40% of marine displays,3 but OLED is expected to gain market share in the coming years due to its superior contrast compared to LCD and LED screens.

However, end users of marine displays are ultimately less concerned with the underlying technology than they are with the features and capabilities of the display system and, most importantly, how many other marine electronics systems it can interface with. Inputs such as HDMI, DVI, DP, VGA and Composite are highly desirable.

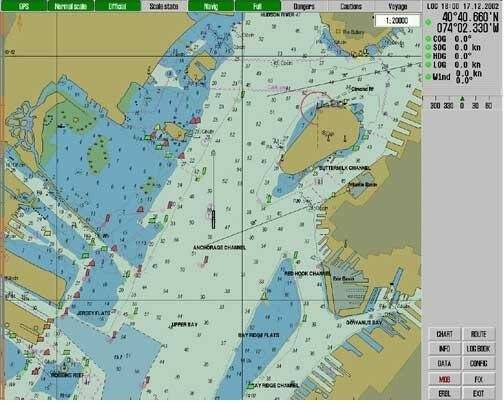

The most critical application for marine displays, which is often integrated into the system, is the on-board navigation. While paper charts have been used by sailors for centuries, vessels now are required to have an Electronic Chart Display and Information System (ECDIS). These systems are regulated by federal rules that specify visual display requirements, as enforced by the U.S. Coast Guard (or in international waters, by the International Convention for the Safety of Life at Sea (SOLAS)).

Example of an electronic chart: essentially a detailed map with information on water depth, location of buoys and navigational markers, anchorages, shoreline features, and more. The ECDIS system integrates the chart data with real-time tracking of a vessel’s position, direction, and speed (Image: Source)

Important marine display capabilities include being sunlight-readable and waterproof. Typically, special films, layers, or coatings are incorporated during the manufacturing process. For example, marine display manufacturer Vartech explains how their “high bright sunlight readable displays use industrial grade enhanced LED backlights to increase luminance without increasing heat. Proprietary Enhanced Light Transmission Technology (ELTT) gives our screens exceptional clarity, wide viewing angles, and maximum light reflection. Optical bonding reduces light reflection and increases ruggedness by providing a solid transparent bond between the TFT LCD screen and the front face of the monitor or touchscreen display.”4

For water and dust proofing, marine displays follow the specifications laid out in the IEC (International Electrotechnical Commission) 60529 Standards document. It specifies an international classification system for sealing electrical equipment against the intrusion of moisture and foreign bodies (called Ingress Protection, or IP).

The casings a marine display also must be ruggedized to help protect the glass screens and internal electronic components. Some displays are built to be mounted on board as after-market or custom equipment, others are embedded components of a marine dashboard.

Additional display features that may be offered by manufacturers include:

- Multi-touch – while touchscreens are common among today’s marine displays, multi-touch displays enable a surface (a trackpad or touchscreen) to recognize and respond to more than one point of contact at the same time, so a user can "pinch-to-zoom" and other functions requiring multiple touch points.

- Dimming – allowing the user to easily adjust brightness across a wide luminance range to account for extreme ambient light conditions

- Shock-resistance – this feature is standard for military vessels that may be in combat conditions

- Night-vision – military vessels may also need display systems that are integrated with night vision goggles

Example of an LCD marine display screen from Winmate with many of today’s desirable features and functionality, including ECDIS charts, multi-touch screen, water/dust projection, and connection ports for NMEA (National Marine Electronics Association) 0183-compliant instruments and systems. (Image: Source)

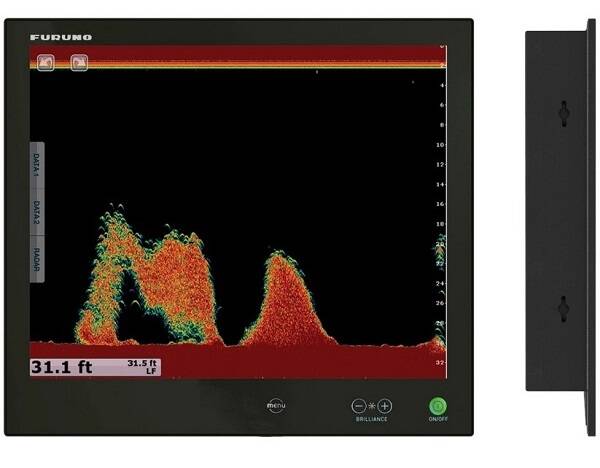

The latest trend in the marine display industry is the development of multi-function displays. With such a wide variety of electronic systems used on board today’s vessels, being able to combine different system functions within one integrated system—using one single display monitor—offers convenience for crew members. It also means that less space is needed to incorporate multiple instrument and system displays within the limited real-estate available on typical boats. Capabilities that manufacturers are now offering in multi-function displays can include ECDIS plus sonar, cameras, radar, and more.

Example of a multi-function marine display from Garmin (top) that combines navigation and chart plotting with sonar capabilities. The screen is treated for sunlight readability and the compact display can connect to multiple other marine electronic systems such as radar, cameras, and more. A multi-touch, multi-function display with color TFT active-matrix LCD with LED backlight from Furuno (bottom) designed for integration into ship’s dashboard system. (Top Image © Garmin, Source,), bottom image © Furuno, Source)

Quality Standards for Marine Display Devices

Like any display product, Industrial and Rugged Display devices require careful design and rigorous testing to ensure that their functionality and performance meet regulatory requirements, operator needs, and customer expectations.

ECDIS Certification

There are two elements of a ship-board electronic charting system: the charts themselves are called Electronic Navigation Charts (ENC), which must be constantly updated to reflect changes, just as a car’s GPS system relies on data and updates from the Google Maps database, for example. The ECDIS is the display system (including both monitor and computer processor) and application that is used to view the ENC. Any ENC must conform to the standards of the International Hydrographic Organization (IHO) before it can be certified for use, and it then it can only be used with an ECDIS that meets the International Maritime Organization (IMO) performance standards or SOLAS standards.

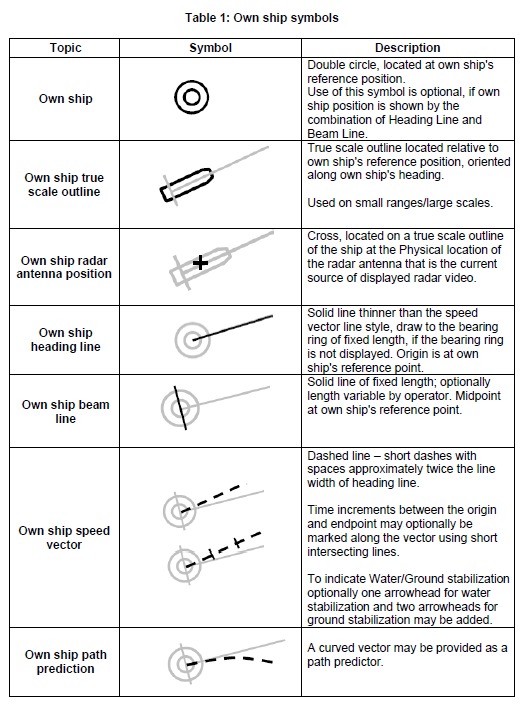

Among the IMO standards are requirements specific to the display monitors themselves. For example, a screen must show the accurate symbols and colors related to navigation, which have been standardized as an international symbol library.

One small portion of the IMO standard symbols that a ECDIS system must display clearly and accurately to assist in navigation and safety. (Image: International Maritime Organization4)

Manufacturers of marine displays can have their systems ECDIS certified by demonstrating that their display conforms to various performance requirements. Visual performance specifications include correct symbol display, screen resolution, color accuracy, and clear visibility under a range of light conditions.5

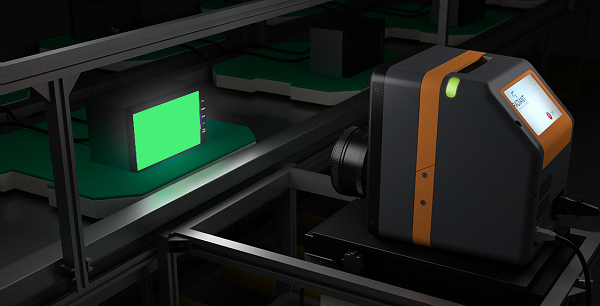

Solutions for Marine Display Quality Inspection

Since the early days of LCD and LED display devices, Radiant has helped manufacturers ensure precise screen brightness and color, as well as detect issues such as mura (blemishes), dead pixels, lines, and other defects that mar the appearance and functionality of displays. Radiant’s display test solutions have been applied across Industrial Display integrations, from aerospace and automotive cockpits to industrial equipment and marine panels. Scientific photometric imaging systems and software enable automated visual inspection to perform complete visual performance testing, view angle testing, symbol evaluation, and anti-glare evaluation.

A Radiant imaging colorimeter is used to perform an automated visual quality inspection of an integrated display device.

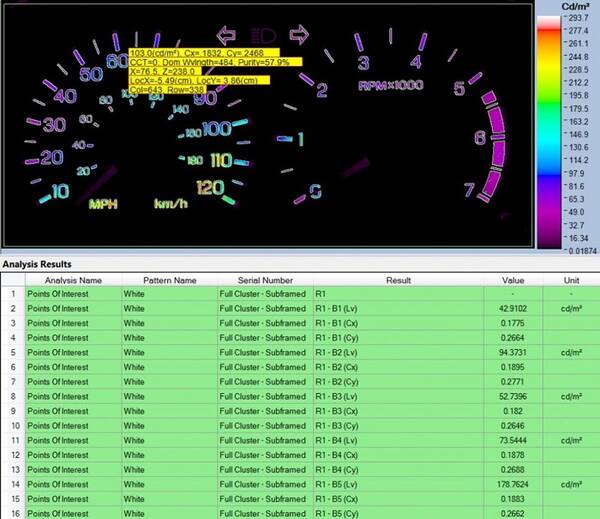

Radiant’s photometric imaging solutions are used to inspect and verify backlit symbols and dashboard or cockpit instrumentation to ensure accurate luminance and color of standard symbol sets. This is accomplished in a single image using thresholding to define specific points of interest for inspection, significantly reducing time for measurement. For example, like IMO standards for ECDIS, the automotive sector has regulatory standards that govern the type and visual qualities of symbols used in vehicle interfaces, as shown in the image below. All symbol sets can be tested in a single image using multiple criteria for luminance, chromaticity, and more.

From TrueTest™ Software, this image shows an analysis of an automotive speedometer region. Each individual illuminated symbol is tested to output its luminance (Lv, given in cd/m2) and chromaticity (Cx,Cy) values.

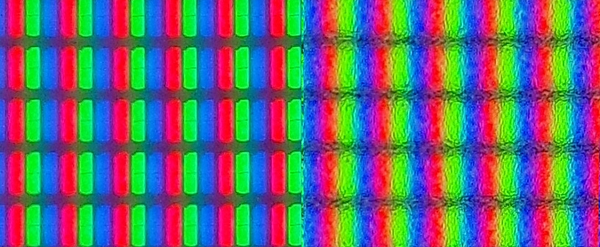

Radiant leads development of solutions to address anti-glare film and coating effects, which are common in sunlight-readable marine displays. Interference patterns from anti-glare films (called “sparkle”) can cause a grainy image appearance on screen. This is due to overlap of the faceted microstructure of the anti-glare layer with the display pixel array. Using a Radiant ProMetric® Imaging Photometer or Colorimeter system with TrueTest™ Software, sparkle can be measured according to human visual perception so that manufacturers can establish meaningful acceptable tolerances for their products.

Measuring the impact of sparkle caused by anti-glare layers is important to ensuring the highest quality display as perceived by a user. This image shows a close-up of the pixel structure in display before application of anti-glare (left) versus after (right) where the sparkle effect is evident.

For display surfaces and screen layers, Radiant’s Advanced Vision solutions enable precise detection of particles, foreign materials, scratches, and cosmetic defects on or within transparent components like clear plastic, film, or glass—such as the multiple layers of touchscreen marine displays, anti-glare films, and coatings.

Using a ProMetric imaging system with TrueTest provides an automated inspection solution that matches the perception and acuity of human vision for both illuminated displays and non-lit surfaces. Leveraging high-resolution sensors with scientific-grade imaging performance, our display metrology solutions produce unmatched image clarity to detect the smallest, pixel-sized defects—at production line speed. Radiant can help keep marine display products “on course.”

Radiant’s ProMetric I-Series Imaging Colorimeter (left) and ProMetric Y-Series Imaging Photometer (right).

CITATIONS

- Industrial Display Market Size, Share & Trends Analysis by Type….and Segment Forecasts, 2018 – 2025, Grandview Research, August, 2017.

- Ibid.

- Global Marine Industrial Display Market – Industry Trends and Forecast to 2027, DataBridge, July 2020.

- “Sunlight Readable Monitors and Displays”, on vartechsystems.com (Retrieved September 18, 2020)

- Guidelines for the Presentation of Navigation-related Symbols, Terms and Abbreviations, International Maritime Organization SN.1/Circt.243/Rev.2, June 14, 2019.

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List