Leading the Way in MicroLED Display Testing

MicroLED displays have been in the “emerging” technology category for the last five-plus years. In the last couple of years, microLED products have begun reaching the market at an accelerating pace and growth in the segment is poised to continue. Analysts are predicting the global microLED market will expand at a CAGR of 78.61% from 2022-2026 reaching total revenues of $ 11.5 billion.1

As a signal of the microLED market’s increasing maturity, it now has its own dedicated industry organization. Radiant is excited to join the newly established MicroLED Industry Association (MIA) to support the development and adoption of microLEDs and microLED display technology. The mission of the MIA is to improve communication, collaboration, and partnership in the microLED arena. It brings together “companies, researchers and organizations active in the MicroLED industry and will provide the ideal forum for solving common technology issues, fostering cooperation and sharing relevant information, resources and tools.”2

Samsung’s The Wall 110” MicroLED television, circa 2020. The company initially introduced The Wall microLED display in 2018. (Image © Samsung Display)

Tracing MicroLED Technology and Market Developments

Radiant has been keeping our eye on microLEDs for a while now and working to address the challenges of inspecting these displays. Below is a collection of resources—including a white paper, articles, and blog posts—that delve deeper into the technology, market considerations, test and measurement challenges, and quality inspection approaches for microLED displays.

White Paper:

Video Case Study:

Articles:

- Progress in MicroLED Fabrication and Quality: Closing the Commercialization Gap, published October 4, 2021, by Manufacturing Tomorrow.

- Measuring and Correcting MicroLED Display Uniformity, published February 17, 2021, by MicroLED Info.

Blog Posts:

- The Landscape of Mini and MicroLED Displays

- MicroLEDs on the Cusp: MicroLED Advantages, Applications, and Production Challenges

A Track Record of Emissive Display Testing

Throughout its history, Radiant has focused on developing visual test and measurement solutions to keep pace with the rapid evolution of the display industry—from early LCD and LED screens to the very latest in OLED, microLED, and other displays for televisions, smartphones & tablets, computer monitors, and AR/VR devices. We have provided solutions for quantifying the output of emissive displays for decades, including the first inspection system for pixel-level measurement of full-color OLED production test applications in 2004. We now apply the same principles for highly accurate and efficient microLED display testing.

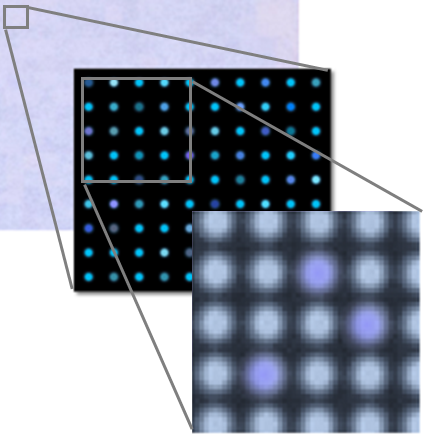

Each pixel of a microLED display is an individual emitter. Variations in pixel and subpixel luminance and chromaticity can cause visible non-uniformity of the display.

Like OLED, microLED quality relies on the consistent output of individual light-emitting subpixels. Inconsistencies in microLED brightness or color, inaccuracies during wafer-level transfer, and other fabrication issues can result in displays with a noticeable non-uniform or speckled appearance. Radiant’s pixel-level measurement methods enable imaging systems to capture highly accurate values of luminance and chromaticity at each emissive subpixel.

Applying patented methods (US Patent 9135851; US Patent 10971044), Radiant’s ProMetric® Imaging Colorimeter and Photometer solutions are capable of measuring all individual microLED subpixels in a display at once to calculate discrepancies between subpixel output. This enables output to be adjusted to uniform values at all display bright states—a process called pixel uniformity correction (PUC) or demura.

To learn more, watch the webinar, Fractional Pixel Method for Improved Pixel-Level Measurement and Correction (Demura) of High-Resolution Displays.

CITATIONS

- Global Micro LED Display Market 2022-26, Infinity Research Limited, August 2022.

- MicroLED Industry Association home page, https://www.microledassociation.com (accessed September 1, 2022).

Join Mailing List

Stay up to date on our latest products, blog content, and events.

Join our Mailing List